Hello and welcome to * MY * NEW * BLOG * <3 <3 <3 <3 <3 <3 <3

Please excuse this ~incredibly long~ first post, there was a lot to write about! My plan here is to infrequently make slightly less long rambling posts reflecting on what I’m up to, making, and thinking about, and to likely focus on the new ‘Double Decker’ wood-fired kiln we designed and built here at Ceramics School this last fall, in addition to other kiln projects past and present, here and elsewhere.

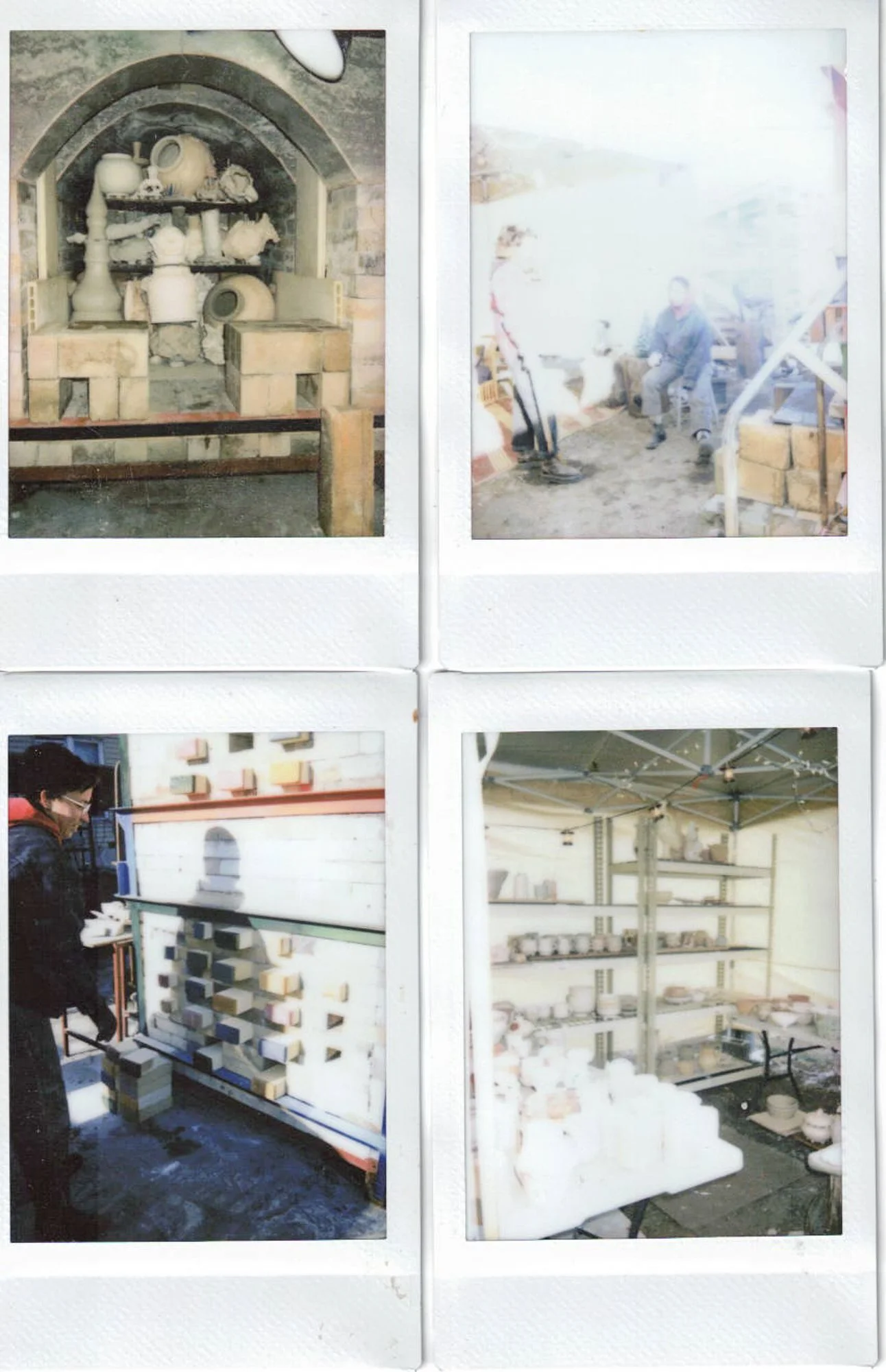

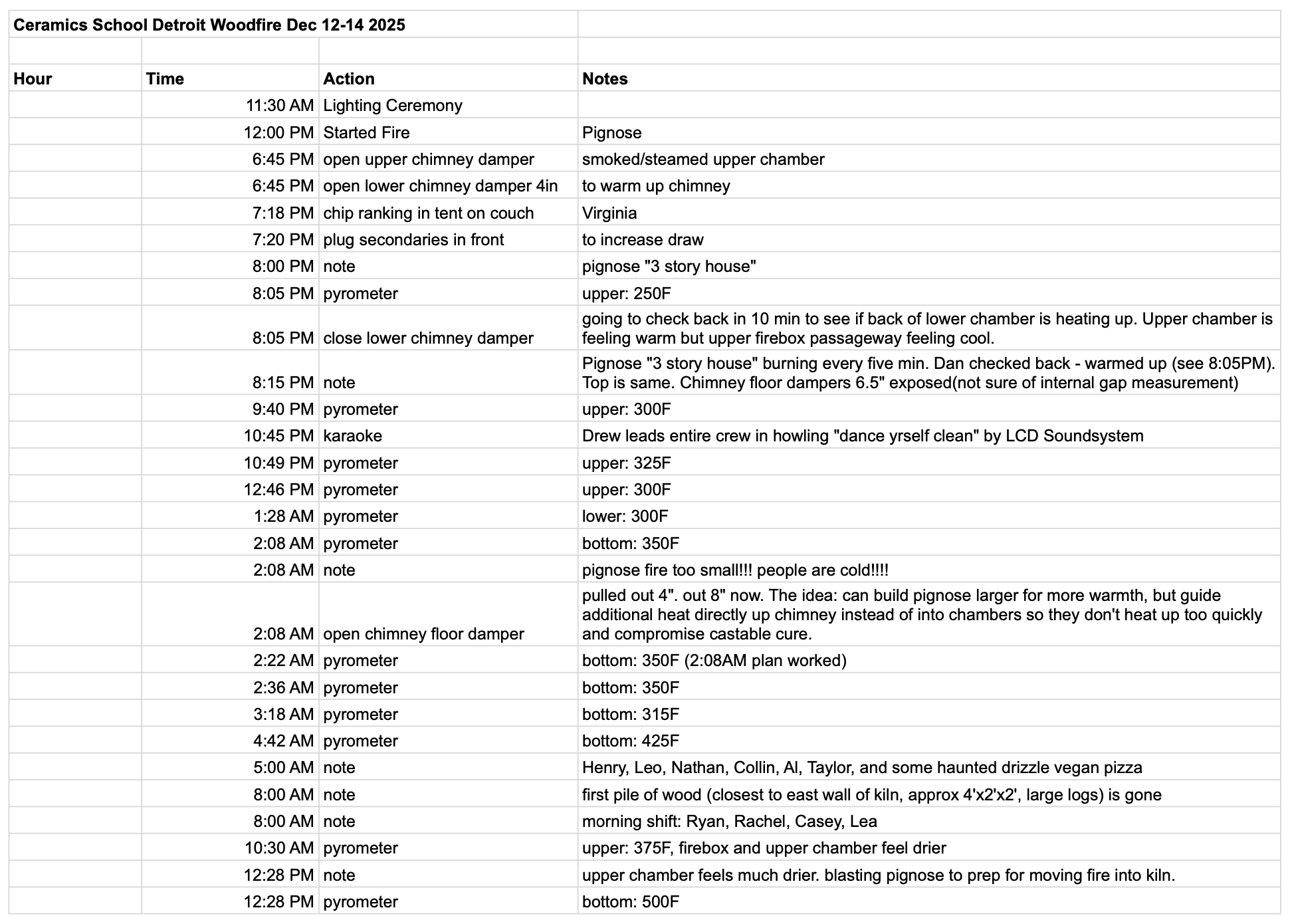

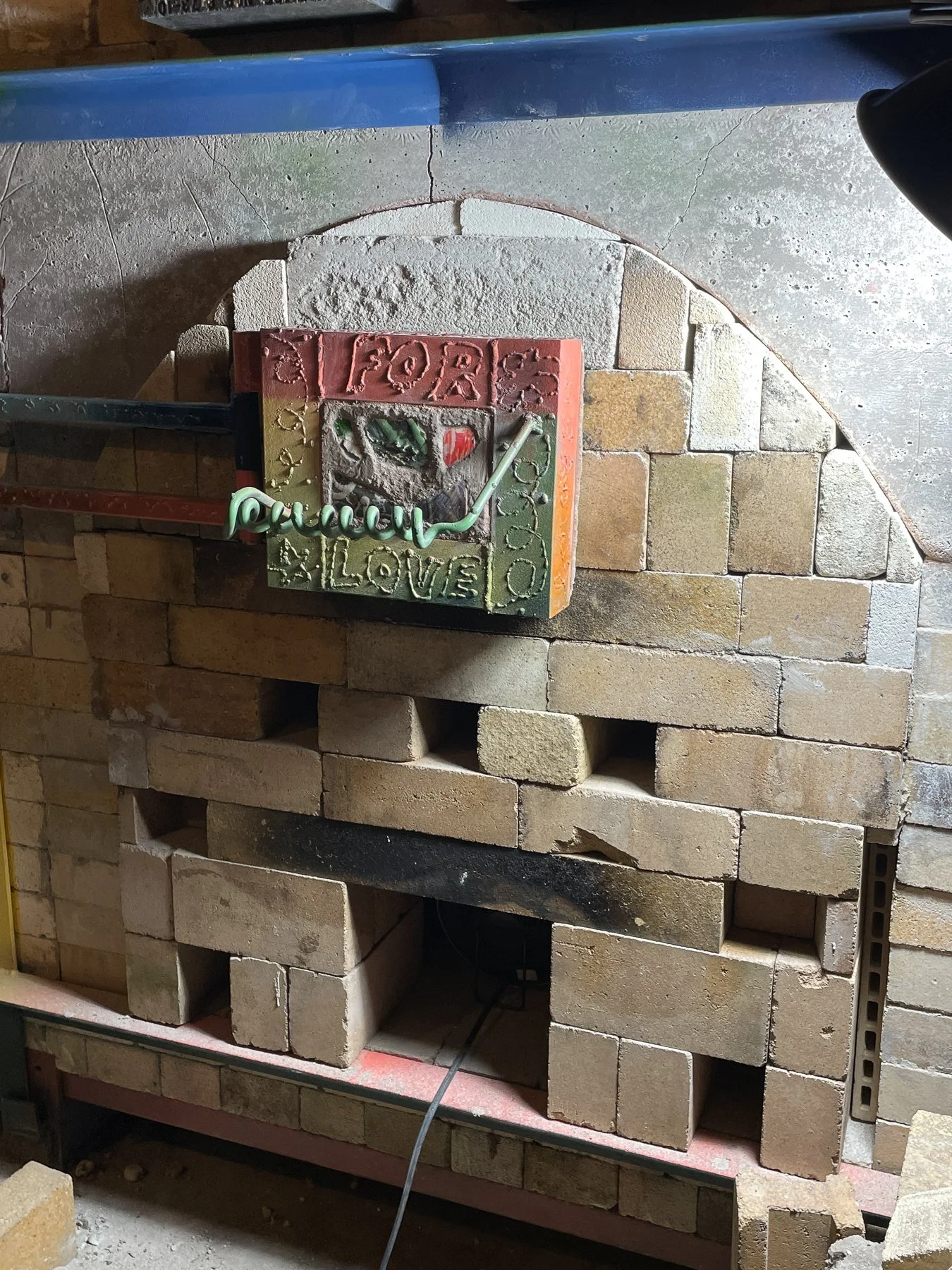

The Hamtramckiln, our new ‘double decker kiln’ at Ceramics School. Fired, cleaned up and ready to go again!

Ceramics School’s 5 year anniversary of being operational in our storefront and residency will be in February and it feels a bit like we’re entering into a new chapter in our studio. With our new kiln and other exciting developments (very soon tba), I’ve been wanting a way to share and archive our activities that isn’t centered on instagram or limited by its image and character restrictions.

That, and whatever dyslexia is has gotten me into a mildly masochistic relationship with written language. I’m so slow, and so bad at spelling and punctuation, and a real sucker for run on sentences, and in so many ways I really just kind of hate writing because I’m really just kind of an in-person kind-of-person. Showing it and saying it come so naturally to me, but articulating myself clearly in the code of the written word is painful, and somehow always feels inaccurate no matter how long I work at it, but also something about that really does hurt so good. Perhaps our time based reality is just impossible to describe in static words, and any critical writer would find their words insufficient, and maybe I just need to accept that instead of finding it painful, or maybe thats why I like clay so much. Because it’s mushy, and time based, and real, and wrapped up in all the things and feelings that I know that I know, but aren’t necessarily always best served by putting into words. And so, my apologies if this is a terrible blog! Ive done my best, refused AI assistance, accepted that this is far too long to request editing from a friend, and have concluded that I am content with my shortcomings whatever they may be.

I kept a Tumbler blog in association with ‘the Salty Dog’ ‘Detroit Noborigama’ kiln I designed and built back in 2011 while Virginia and I were students living at Fortress Studios in Detroit’s North End Neighborhood, and I’ve been thinking about how much I really enjoyed that practice, and maybe nostalgia is just getting the best of me in a moment of doom scroll fatigue, but I think this is more about embracing my ceramic nerd self, and finding a more idealistic way of participating online. So much more has happened in the 15 years since I last kept a blog than I could possibly recap in any meaningful way short of writing a memoir, but I do feel like I need to get into the long arch of my thoughts and experiences at least a little bit if I am going to illuminate so much of what feels so exciting and special about this new kiln.

The only image that comes up from my old blog on the Wayback Machine. Alanis lived on a ledge in top of the front chamber of The Salty Dog and was stolen at some point. My understanding is that kiln never got to temperature again after she went missing…

An ultra compressed timeline would be something like: in 2013 Virginia and I move from Detroit to go to graduate school in Alfred, NY where I designed and built our Mobile Anagama kiln that I drove around the country doing workshops with, in 2016 we moved back to Detroit (Hamtramck), in 2017 we got married and had the incredible good fortune to become the stewards of our house and storefront, in 2019 we started Ceramics School as a pop-up down the street at Popps Packing, and in general we’ve spent every spare moment and dollar we’ve had over the last 8 years doing our best to make this place into the home, studio and residency it is today.

We set up the Mobile Anagama up in our yard as soon as we got our house, and started collecting fire bricks for the larger kiln we knew we someday hoped to build. Bricks from potters who were deaccessioning their studios or had passed away, bricks spotted on fb market place, bricks left in an abandoned house whose chimney was used as part of a student’s kiln project, bricks from friends Ken and Randal, and bricks that were once slated to become part of Dow Chemical’s incinerator before the EPA shut it down in the 80’s and Dow sold them at auction to friends of the son of the old man who had an apple orchard down the road from my parents where I would ride my bike to pick apples and mow the lawn for 4 dollars an hour as a kid. I learned about those bricks when an old friend purchased a house back in our home town a few years ago and the guy he purchased it from was there cleaning out the garage when we stopped in to check out the house, and he had the same last name as the old man with the apple orchard, and we got to talking and he remembered me, and said his dad said I was the only good help he ever got on the orchard, and that he and his friends had the mother load of fire bricks if I might be interested in such things. He does indeed have the mother load of bricks although all of them are of very strange sizes and shapes and being slowly consumed by the thick forests of greater Midland, MI. The only bricks we purchased new was a pallet of very special k26-60 bricks (2600 degree rated, 60% alumina insulating fire bricks (IFB)) that are both highly insulating and able to withstand the corrosive atmosphere inside of the wood fired kiln. Those bricks came from the lovely folks near us at Sterco in Sterling Heights who also donated the better part of a pallet of yet more, you guessed it, bricks.

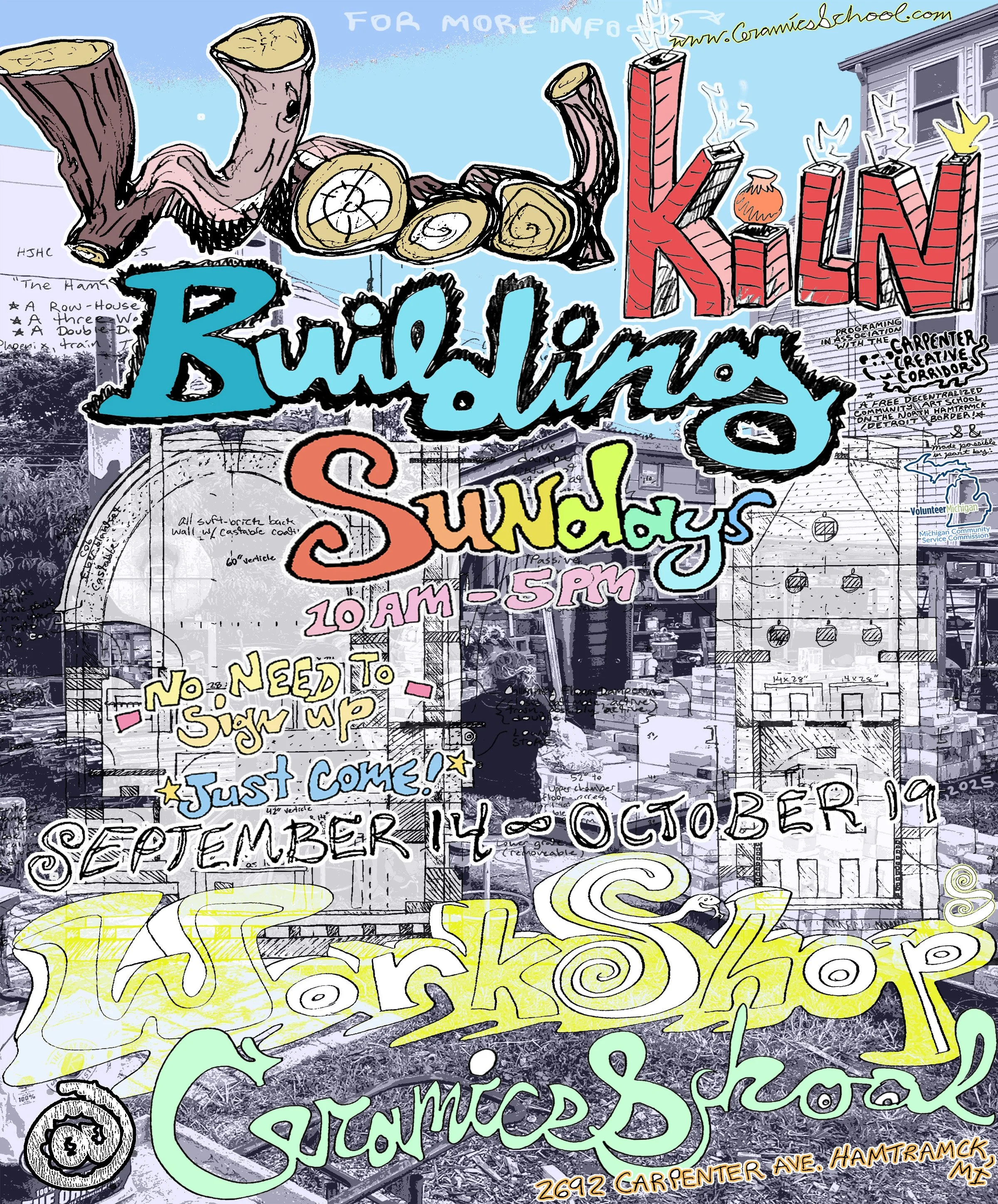

And finally, thanks to a Michigan Community Center Grant we received through the Michigan Community Service Commission as part of the Carpenter Creative Corridor (CCC), a decentralized community art school along the north Hamtramck/Detroit border, we were also able to purchase 3000 lbs of castable refractory material (k-30 last-o-lite) in the form of sixty 50lb pound bags and 20 new kiln shelves this last summer, and that was the moment when this project turned from dream to happening, and we finally settled on a design and got to work! So many thanks to our amazing friends, neighbors and CCC collaborators Faina at Popps Packing, Richard and Liza of Play House Labs, Shanna of Mothlight Microcinema, and Jenna our grant organizer who we are ever inspired by and who did so much to make the CCC happen!

To start this new kiln chapter we first had to first end the previous one, so last summer we celebrated the 10 year anniversary of our Mobile Anagama kiln with a final firing here, and we then disassembled it, moved it to the back of a field on uncle's farm outside of Grand Rapids, and began to prep the site here for the new kiln, and to collect the metal working tools that would be necessary to build it. *If interested in making use of our old mobile kiln I have dreams of it being a sort of roaming gnome and would be happy to chat about what happens next with it…

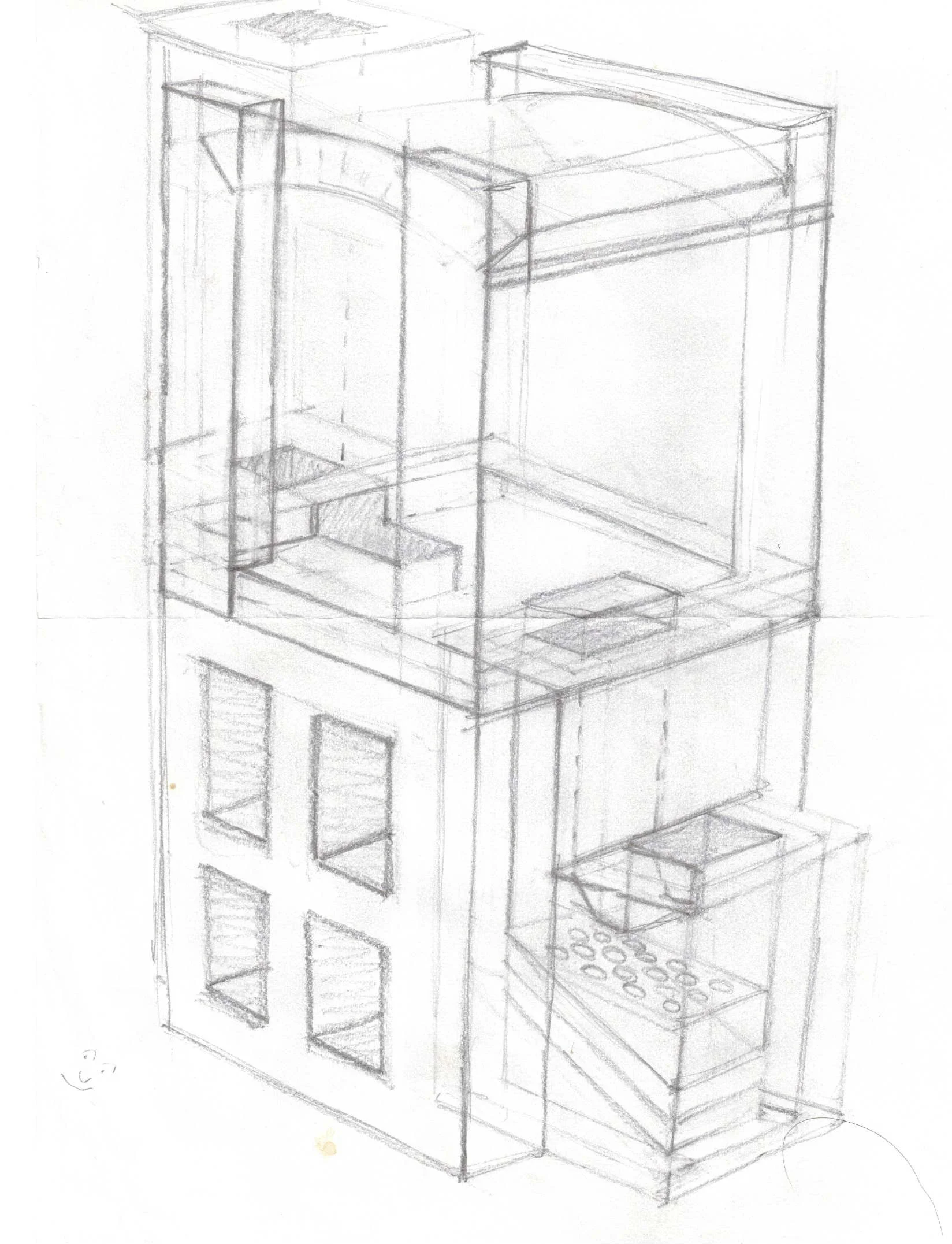

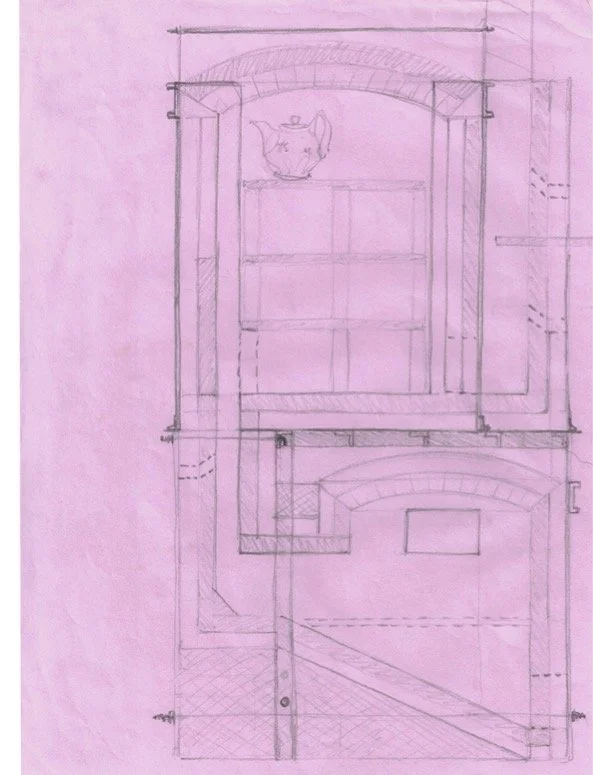

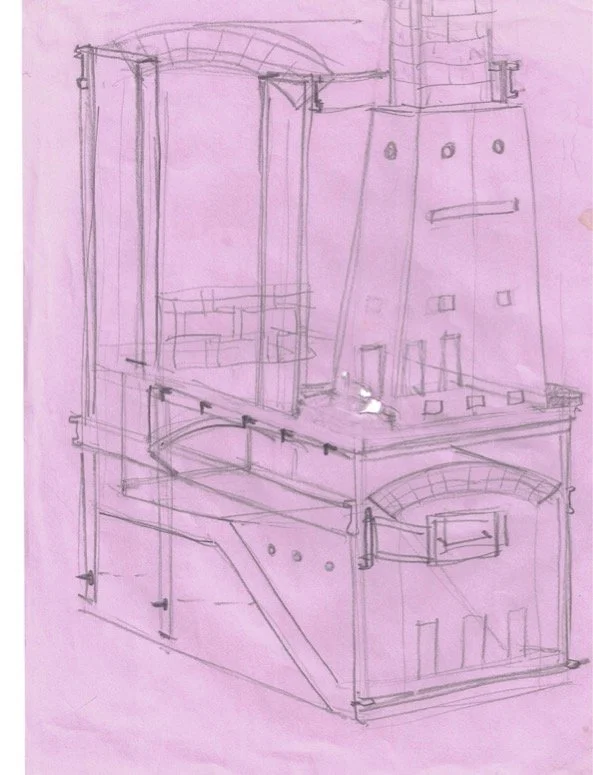

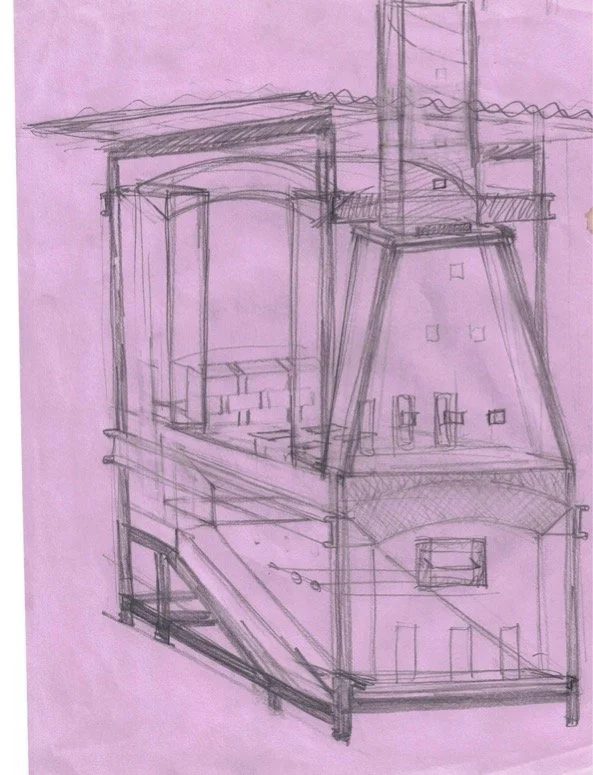

We thought for a long time that the new kiln we would build would be a larger stationary anagama type kiln, but concerns about its scale and it producing too much smoke, had me going back and forth on the idea, drawing kiln after kiln late into the night on our kitchen table, searching for something that felt just right. It had been time for the Mobile Anagama to go because it was no longer large enough to accommodate the objects and interests of our studio, and because we wanted a kiln that was more physically accessible especially regarding the kiln loading processes. It had been a great little kiln though, and it turned out that its mobility not only allowed it to move, but also to cut through red tape. What is mobile is also not ‘permanent’ and as such is often not subject to rules regarding structures, and so mobility, or the possibility of mobility, kept coming back up.

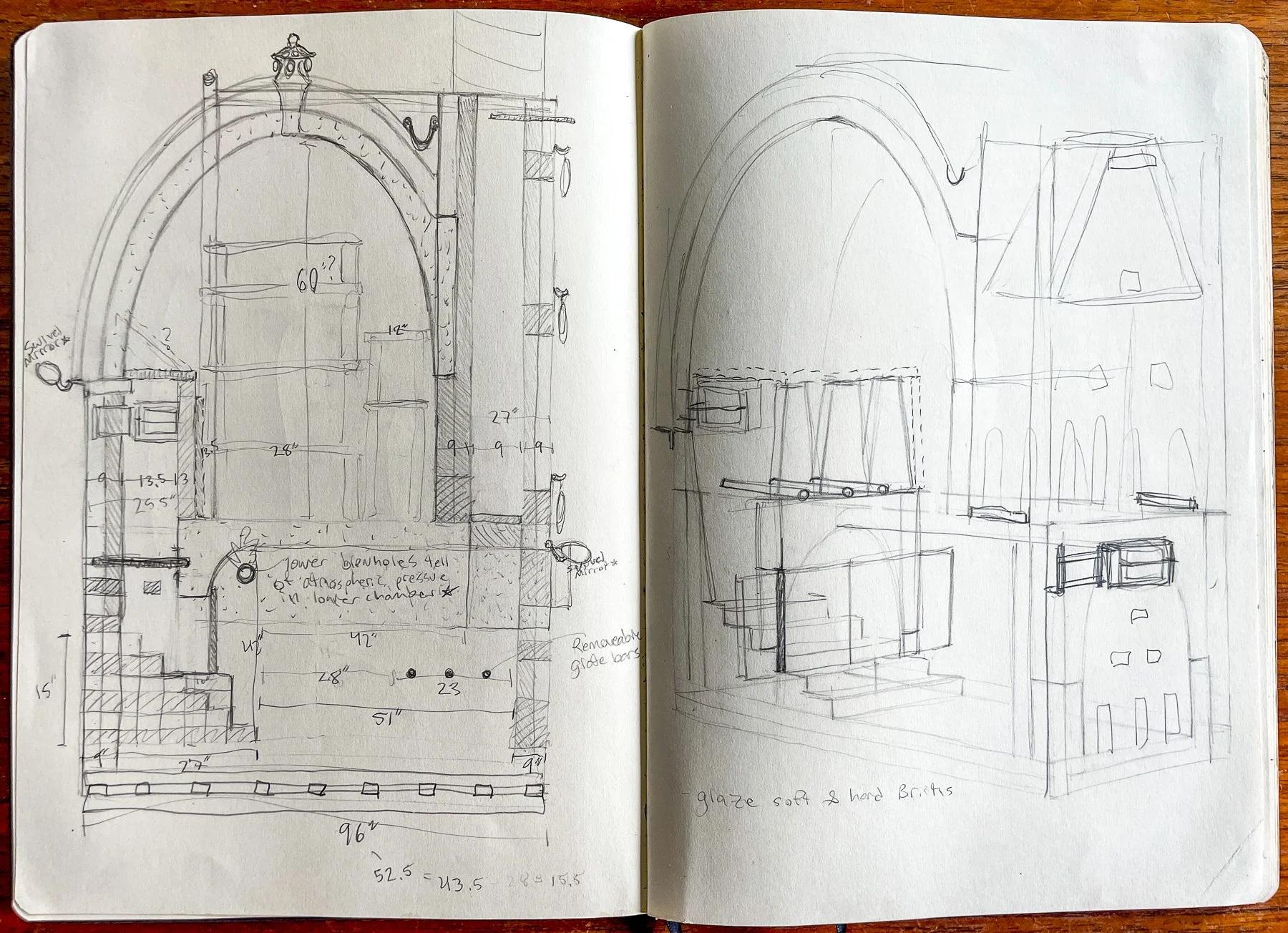

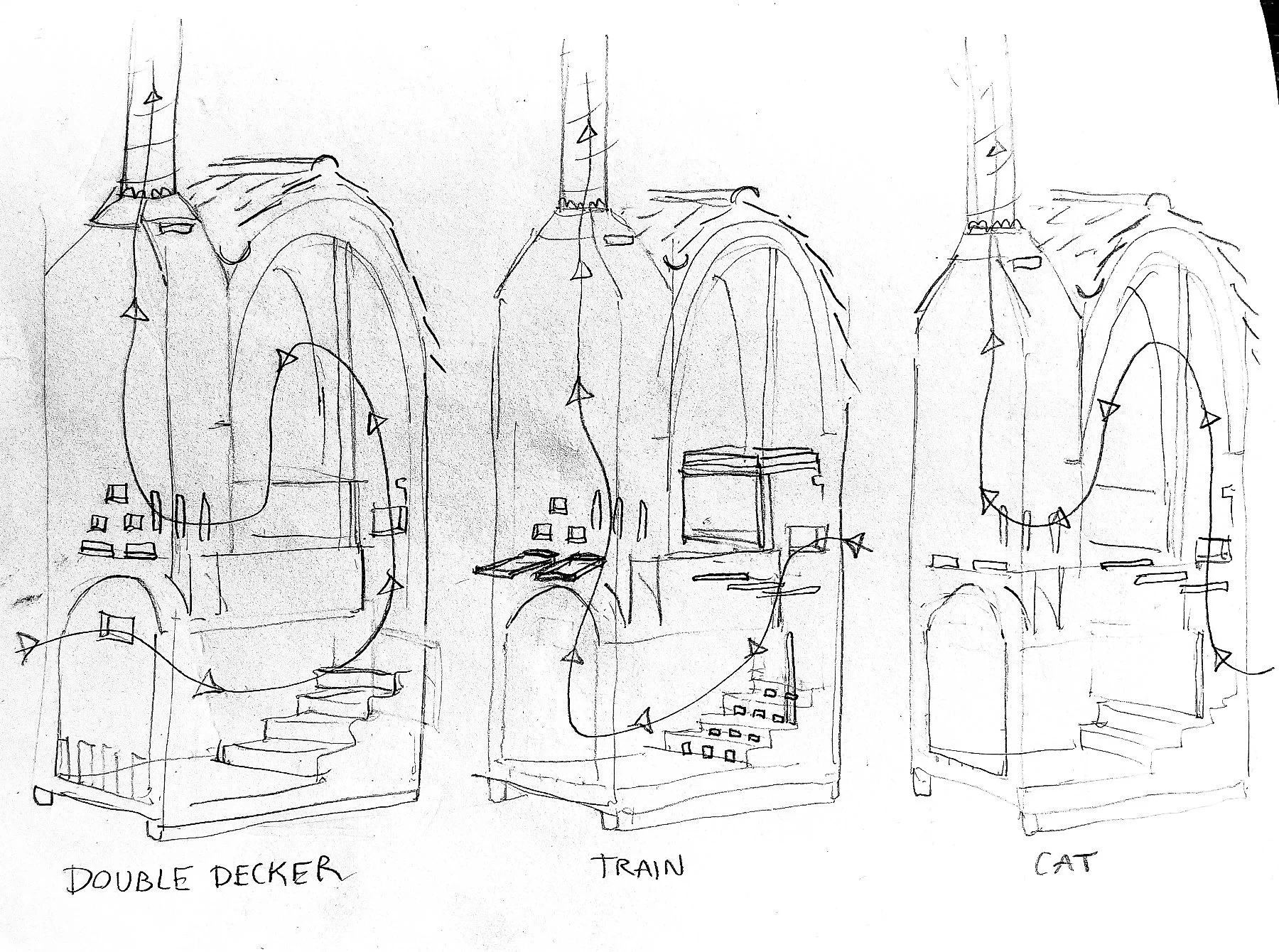

I led a kiln building class with a small group of students at CCS in the fall of 2024 where students designed, built and fired mobile kilns on carts. The designs were inspired by Lisa Orr’s rocket kiln design, making use of old eclectic kiln bodies as the ware chambers, and one of our goals was to hold a mobile kiln parade, but that never happened. A mobile kiln parade is still very much on my bucket list.* But after building and firing those little rockets, I kept thinking about and drawing rocket kiln related concepts. Thinking we could build one here at our studio to use as a mini woodkiln to tide us over while the big one came together, and we did end up doing exactly that last spring, and it's been great, and I’ll write a future blog post about it as well. But as I continued to draw rocket kiln related concepts I tried incorporating the sloped floor of The Mobile Anagama, and started imagining how objects might fit additionally into a lower firebox area to receive more direct and bold firing marks. As I kept drawing that area got larger and larger, and the complexity of elevating the one chamber above the other seemed beyond my metal working capacities at the time, and it also felt like a missed opportunity to have heat radiate up through the ceiling of a lower chamber that could also be the floor of an upper chamber, so I started making drawings where the upper chamber sat directly on the lower chamber.

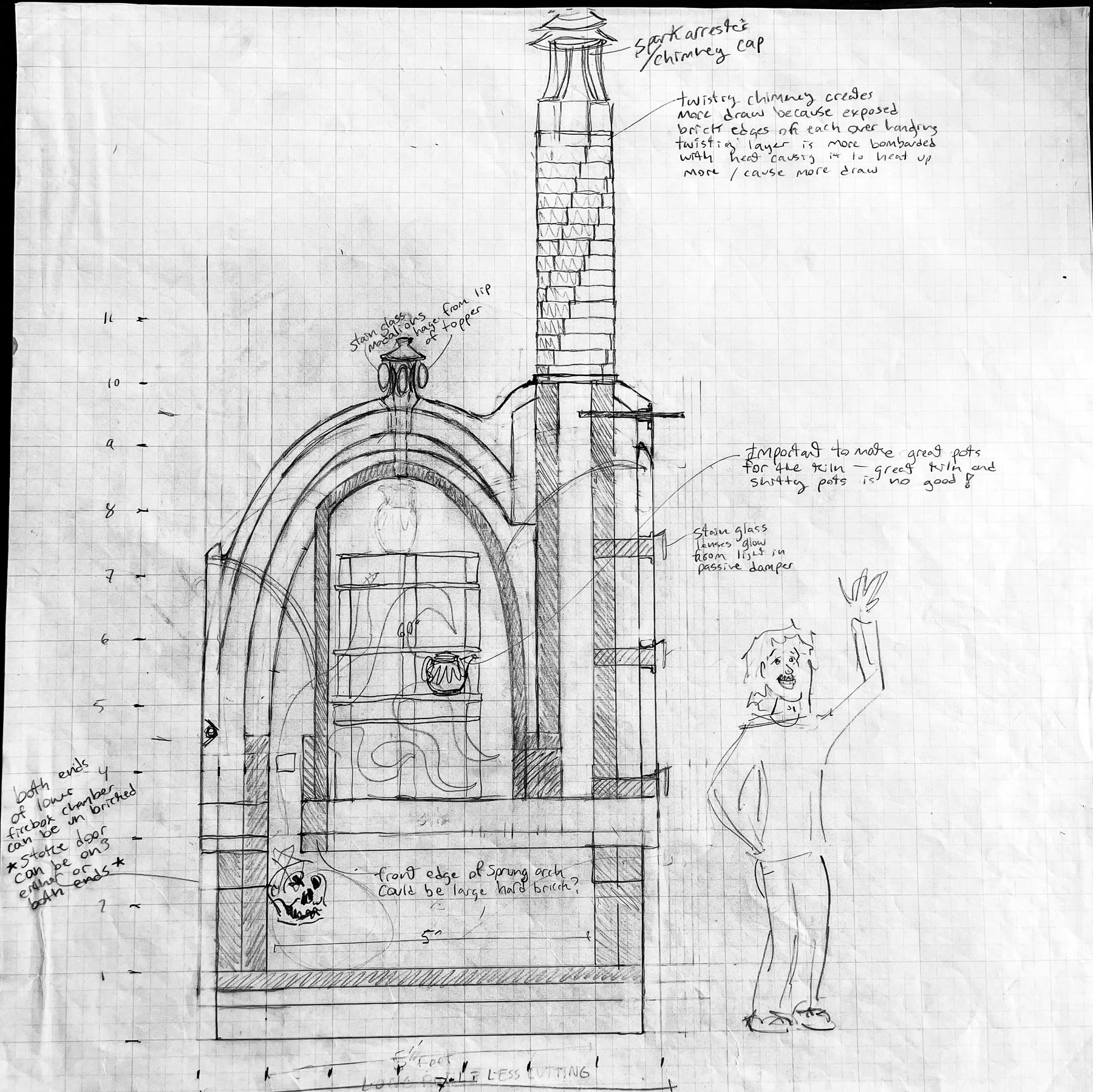

Virginia and I have been co-teaching the wood-firing classes at Oxbow for the last three summers and will again this coming June, leading groups of students to make, load and single fire their 80 cubic foot catenary cross draft kiln, that we’ve come to affectionately know by the name ‘Nom Nom’. I’ll write Nom Nom her own future blog post as well, as her architecture has both taught and confused me more than maybe any other kiln I’ve ever known, but for now I’ll just say that one of Nom Nom’s more interesting features is that she seems to require delicate and precise use of her passive dampers, which in her case are six 4.5” wide 10” tall holes at the base of her very large chimney. Passive Dampers that may be feathered more or less open by bricks that stand and pivot in the openings. Beginning to understand the possibilities of what has long felt like these most mysterious and mischievous bits of kiln anatomy, has now made me somewhat of a passive damper enthusiast. Viewing through them into the chimney base, through the flues, and into the ware chamber of the kiln offers a very accurate way to observe what's going on inside the kiln, where the heat is building, how dense or opaque the fame is, if the flame is favoring one side or the other, things that can be very useful in making precise decisions about when and how much to stoke, etc. However, as Nom Nom’s passive dampers are located at the base of her chimney, you either have to go around the side of the kiln to view through and adjust them, or what we more often do is have a person stationed in front of them for the entire latter part of the firing.

Images from Oxbow times

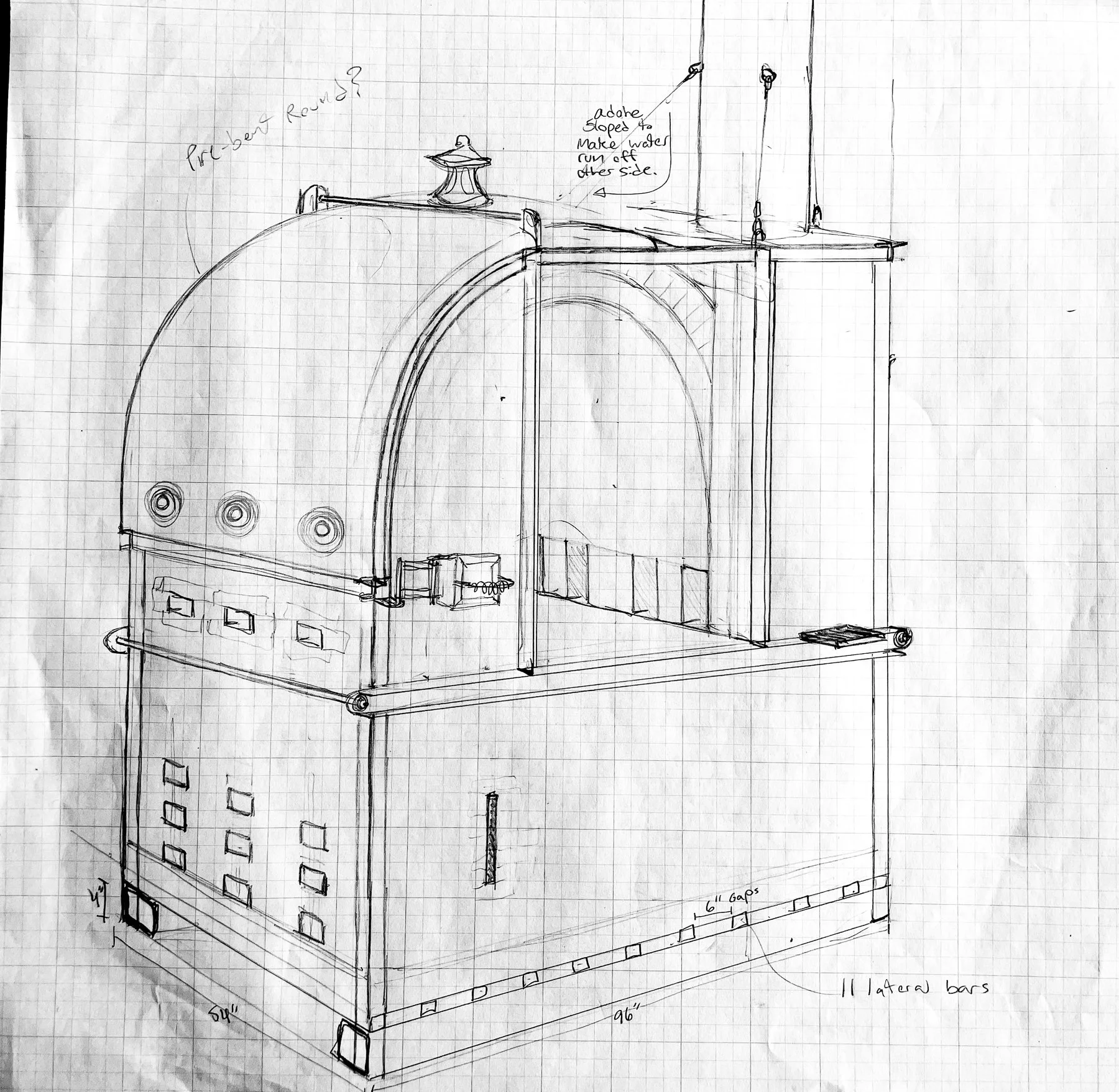

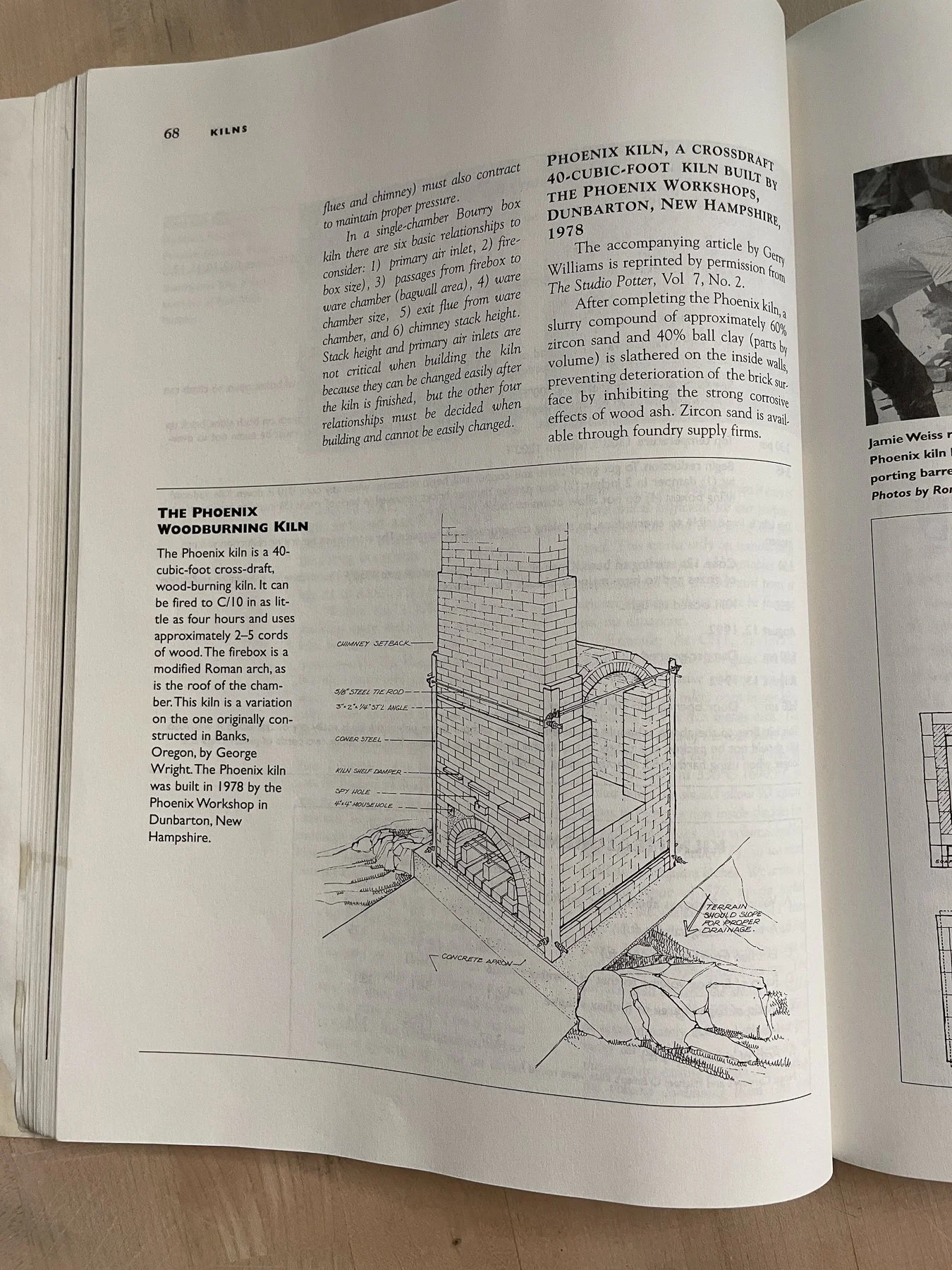

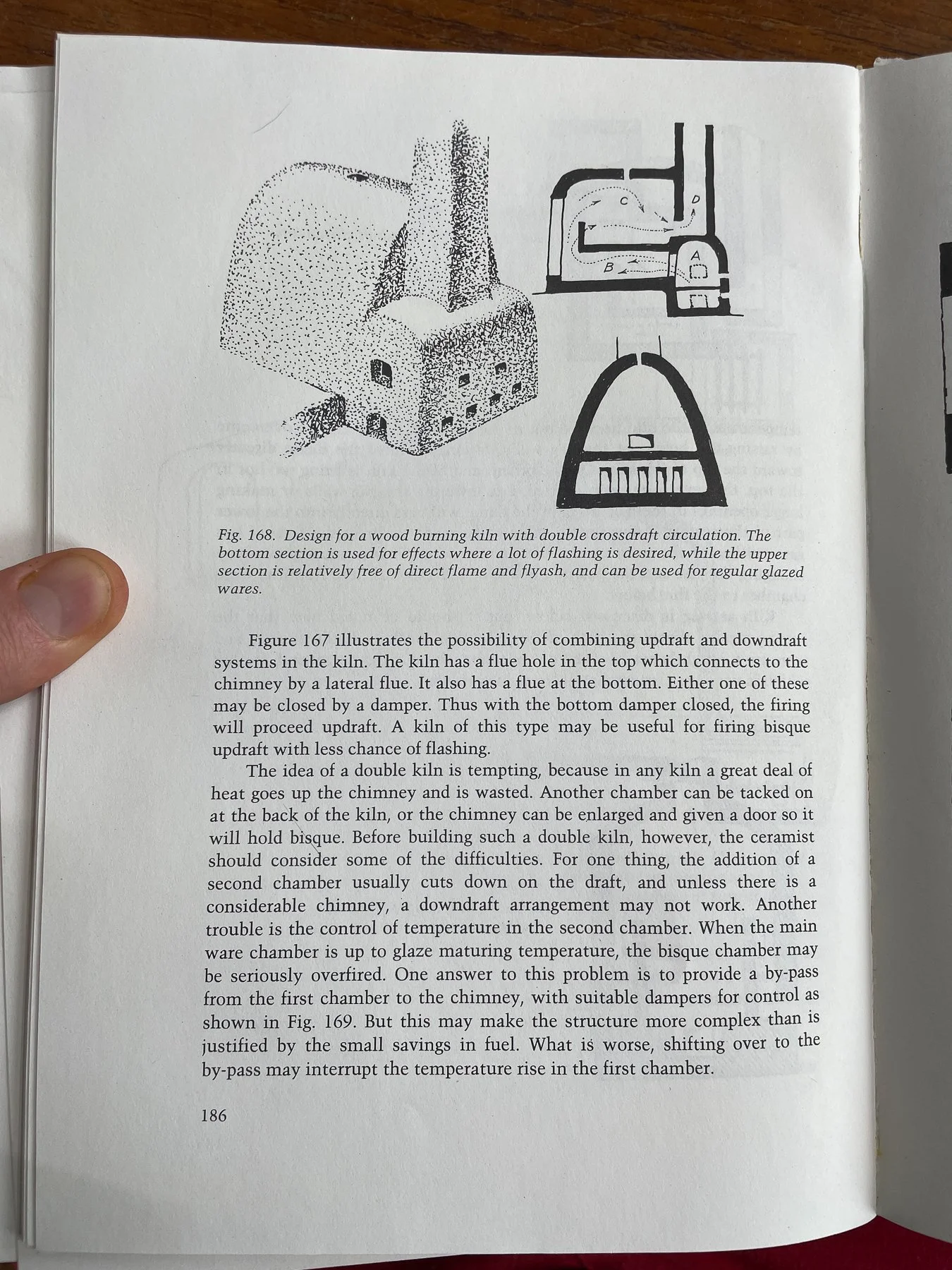

While drawing and redrawing this emergent two chamber stacked design I was really excited about the possibility of being positioned at both the back and the front of the kiln at the same time, making for a kind of command center where all of these things, the primary air, fuel, passive dampers, and observation of the inside of the kiln could all happen. Just as the first renditions of the design started to coalesce in the fall of 2024, we took a trip to go to a wedding on the east coast, stopped in Alfred to visit friends and faculty, and I wound up talking with then first year grad student GH Wood about kiln designs, and when I showed him my latest drawings he said, ‘oh you mean like a Phoenix Kiln?” to which I replied, “What the hell is a Phoenix Kiln?!” To my astonishment, yes, a Phoenix Kiln was indeed almost exactly like what I had drawn, though my design intended for the lower chamber to be loaded with wares as well. In the time since then I have come to learn that the general Phoenix Kiln design concept is an old one, and its has also been called a Philosopher's Kiln and a Ito Koi Gama. Somehow I had missed the drawing on p.186 of the second edition of Daniel Rhodes Kilns and I didn't have a copy of Jack Troy’s Wood Fired Stoneware and Porcelain so I hadn't seen the included reprint of Gerry Williams’s article titled “The Phoenix Wood Burning Kiln” from The Studio Potter, Vol 7, No. 2.

Learning of the preexistence of this design was a lovely confirmation of my thinking that it would work, but for some reason I still wasn't entirely convinced that I had worked the idea all the way out for myself, so I kept drawing it. At one one point to all but gave it up, thinking we should just take this opportunity to just risk it and build the big anagama, and we even went as far as to mark out the site in preparation for digging the anagama’s foundation, but I couldn't stop thinking about passive dampers, and viewing through them, and how they might be a hole in the straw keeping the Sprite in the cup or in this case the heat in the kiln, and how they might either cool a chimney with cold air or heat it by providing air into the chimney with which to combust excess fuel entering it, and I started thinking about the possibility of an opening between the fire box and base of the chimney, and what could come from allowing some amount and heat and fuel to bypass the kiln’s ware chamber. And then at some point, I think while taking a shower or driving, lighting struck and it occurred to me that with said opening between the chimney floor and the lower chamber, a temporary lid could be constructed over the upper firebox and the bottom chamber could be fired independently as a train kiln that would fire in the opposite direction. As soon as the idea came to me, I was obsessed with it, I couldn't stop thinking about its possibilities, and how it might work, and I kept drawing it to get the bricks and proportions, and features just so, until I didn't ever want to see a piece of graph paper again, and eventually Virginia and I decided we should build it.

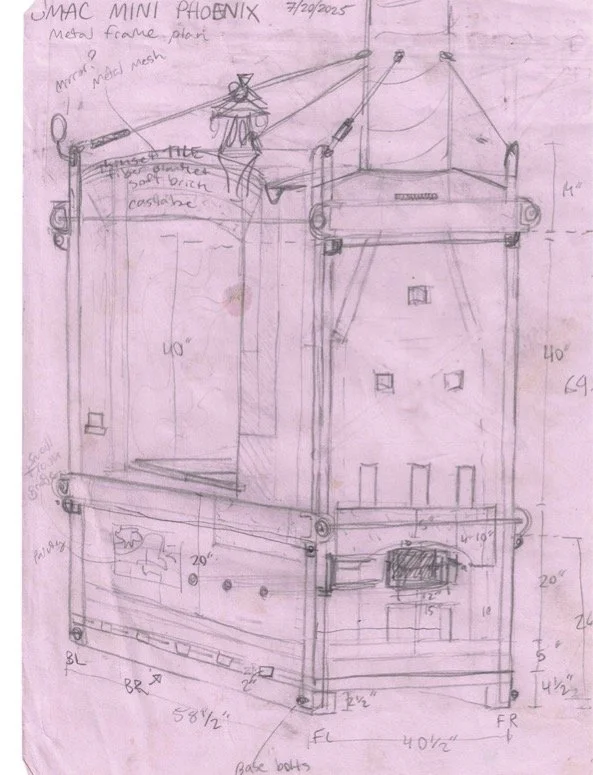

Over the last year a $200 50-year-old arch-welder from FB marketplace with a 60ft 50amp plug has become a new close friend while working under an EZ up in our yard weather permitting. We leveled the cement where the kiln sits, and once I was finally comfortable with my arch welding skills I fabricated the kiln’s metal pallet base from steel recycled from the Old Blauuw kiln they decommissioned at Pewabic earlier last year. The length of the two large recycled beams that sit under the length of the kiln was the final determining factor for the length of the kiln, and I designed the rest of the kiln from there.

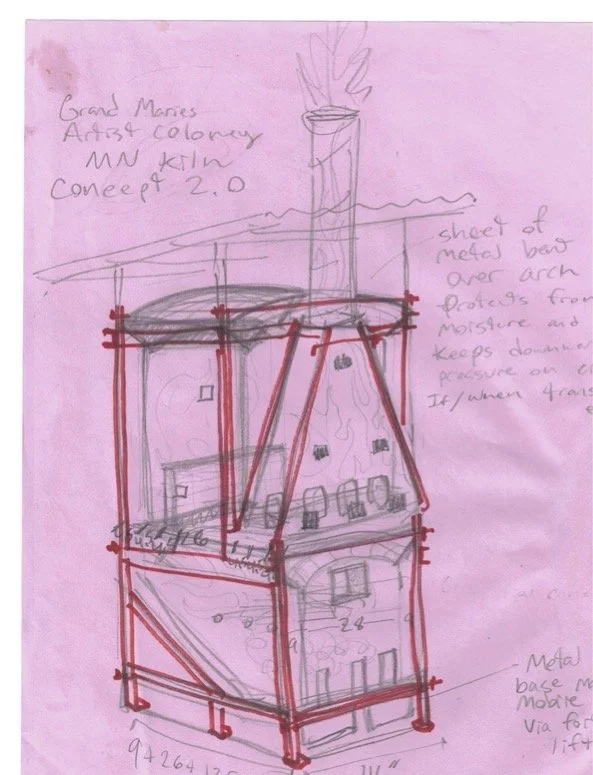

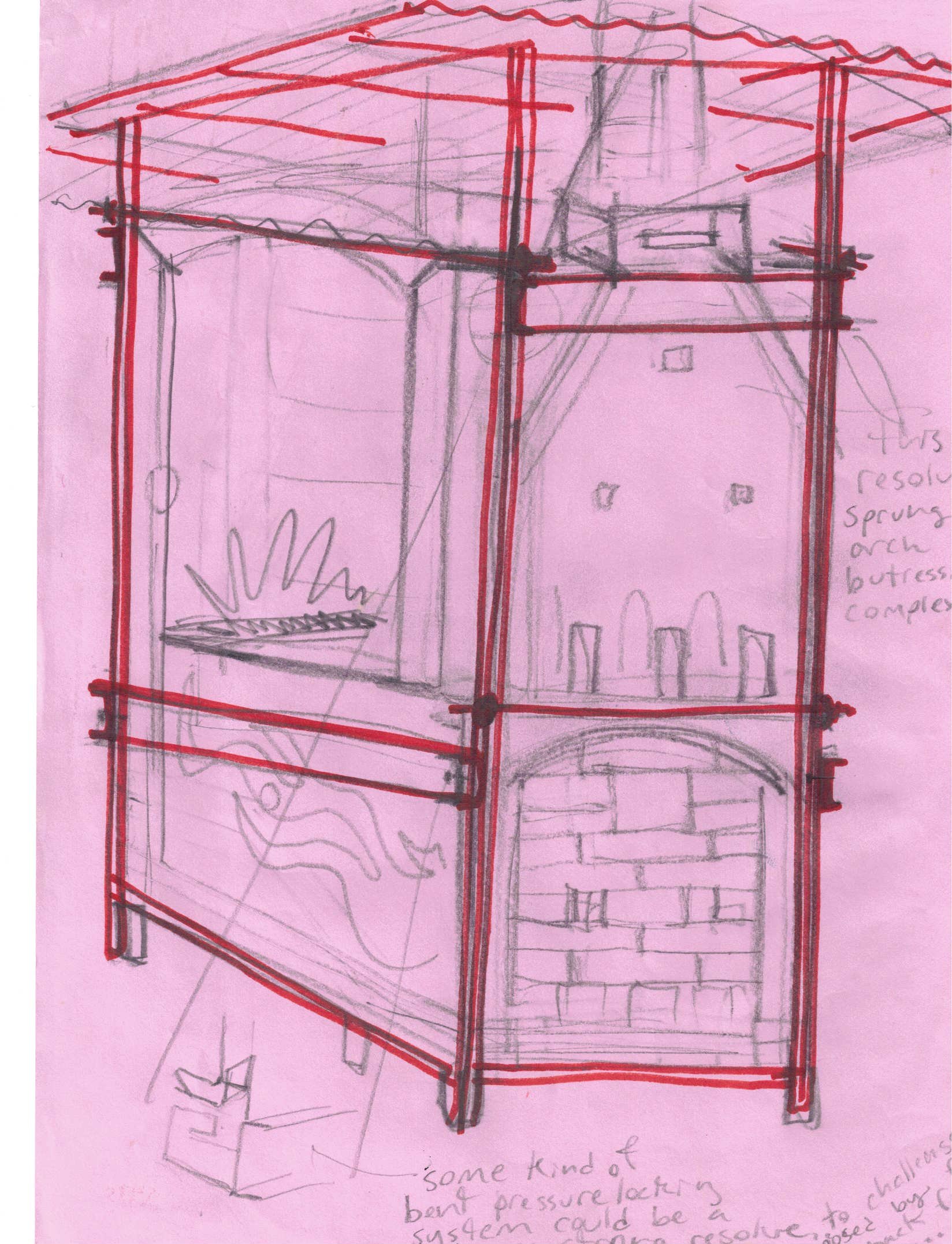

We laid the first bricks in July with our angelic and then freshly engaged friends, Daniel and Michael, but I had to shift my focus in August towards building and firing a mini wood-fired phoenix type kiln as a week long workshop at the Grand Marais Art Colony in Grand Marais, MN. That kiln is very much the little sibling of the kiln we just built here, and I’ll be leading another week-long workshop around it again this August of 2026. I intend to write its own future blog post as well after that second firing.

Mini Phoenix kiln built as a workshop at the Grand Marais Art Colony in Grand Marais, MN August 2025

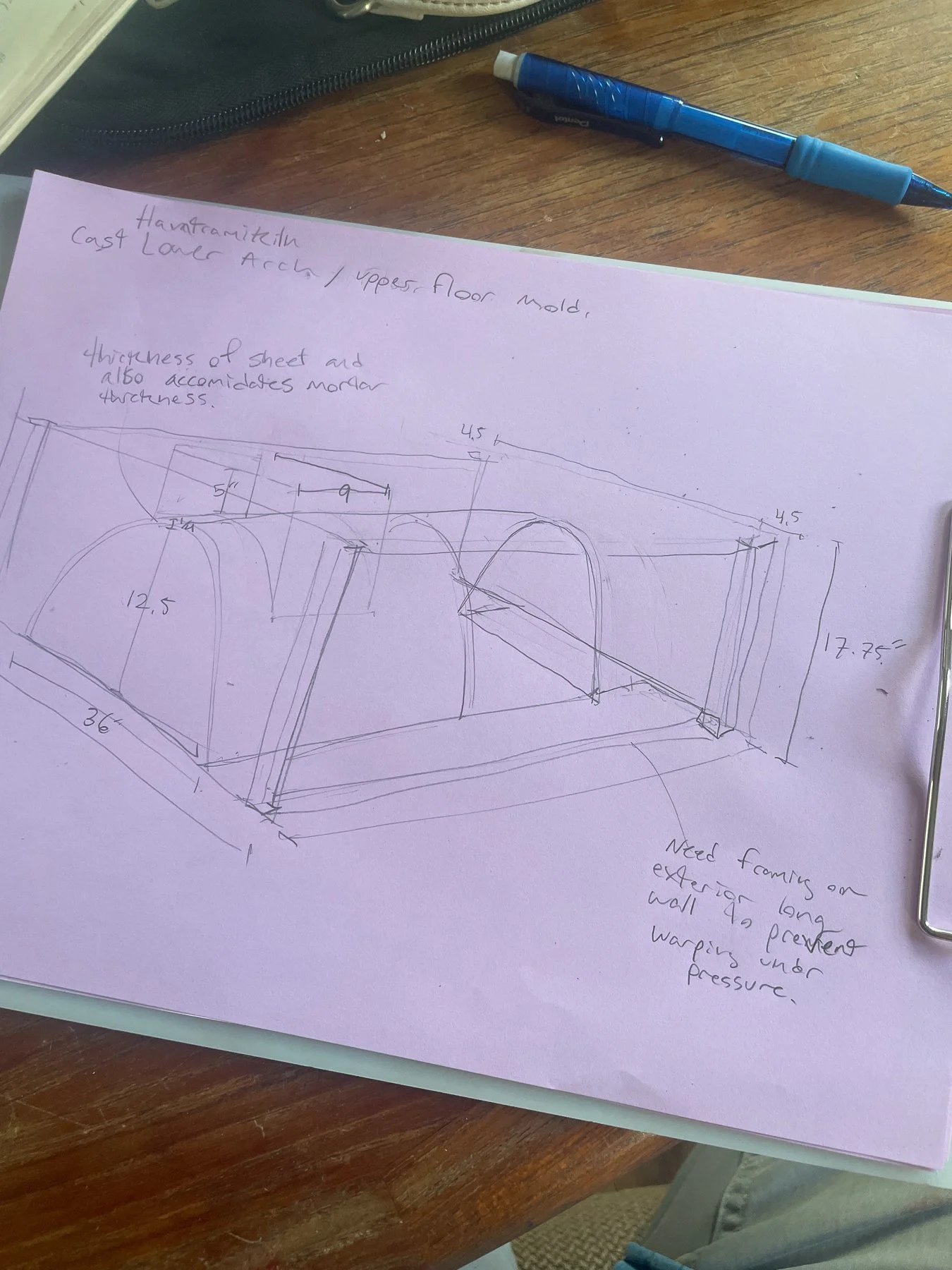

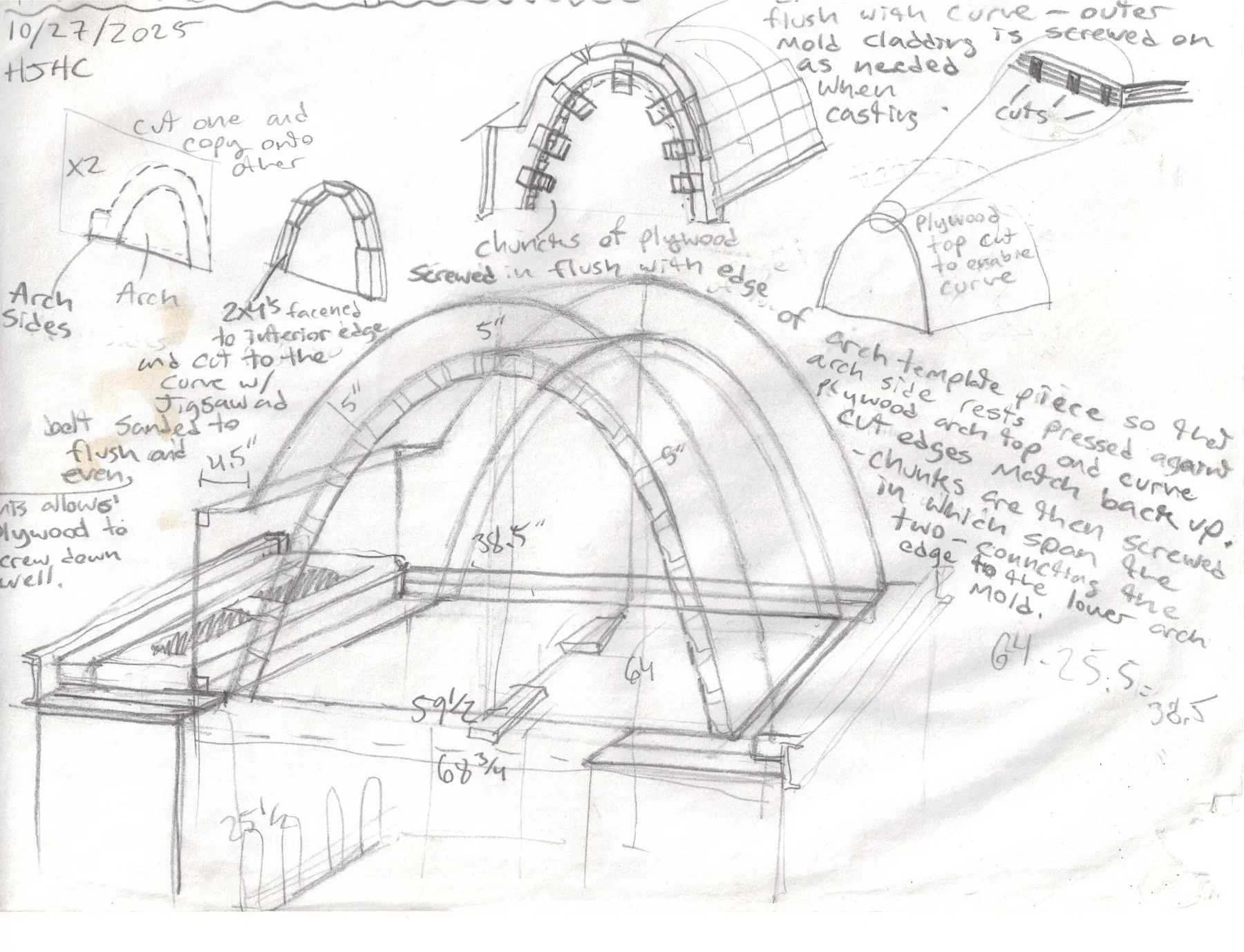

And finally after years of anticipation and planning, in September we began a series of free public kiln building workshops on Sundays that set a critical forward moving tempo for the project. The kiln building began in earnest with the workshops and each week Virginia and I worked to get everything ready for the next, organizing tools and materials, building molds for the kiln’s two large cast arches, fabricating and welding the kiln frame together as it continued building up, getting the terracotta roof tiles, laying yet more bricks, etc, until fall turned abruptly into winter and all the sudden we were loading and then firing the kiln.

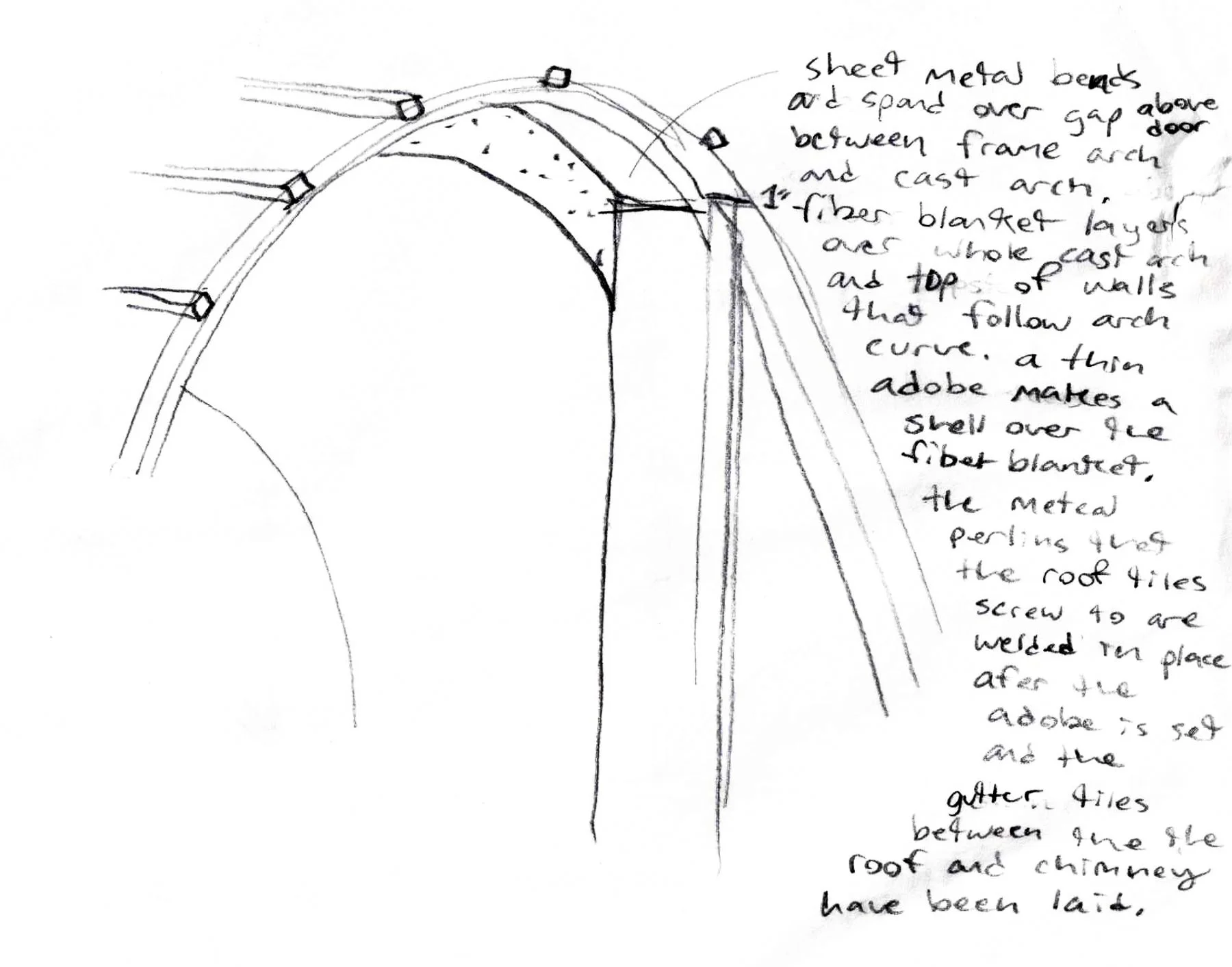

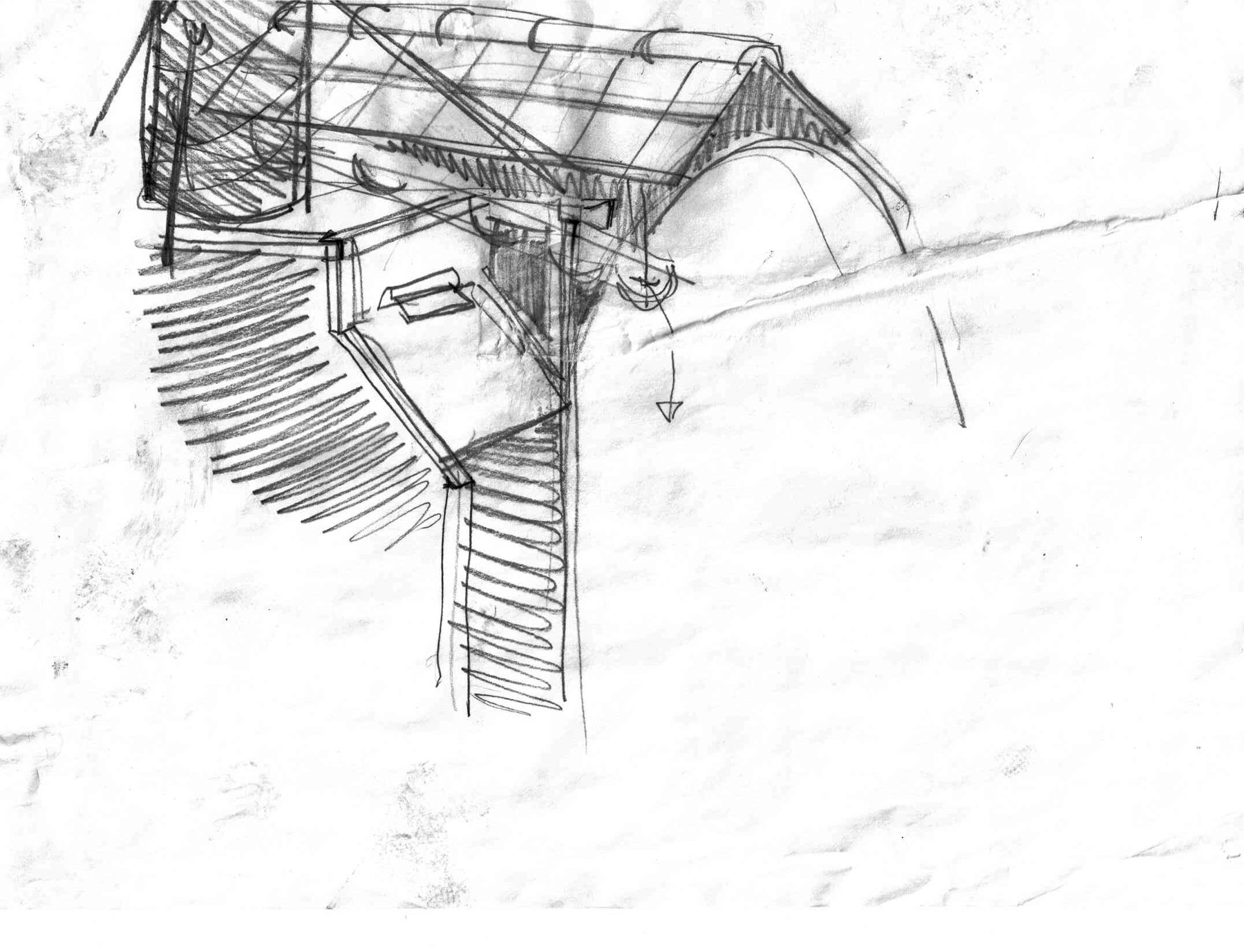

The whole thing felt serendipitous in so many ways, Taylor and Al were our kiln building MVPs and showed up every sunday to make it happen and we could not have even sort of pull it off with out them. Construction came down quite literally to the last minute while Colin and I worked into the night to finish putting the tile roof on just as the snow really started to come down on the Wednesday before Thanksgiving, and winter really hasn't subsided for us since then. The roof tiles themselves were quite the story. We had initially planned to cob, mortar and tile over the kiln in place of a roof, but were never entirely pleased with that option, and after much reading about cob I decided it was an inadvisable option as it would likely quickly be degraded by our frequent freeze thaw cycles here in Southeast Michigan, and in my effort to find a roof option that would be affordable and not hideous it occurred to me that terracotta roof tiles would be ideal as they are ceramic, easy on the eyes, heat resistant, able to accommodate movement from their substructure well because they are all individually connected, and could easily be found second hand for cheap.

I also just love terra cotta tiles in part because for my thesis exhibition at Alfred I worked with the historical society to get access to the then shuttered 1893 Worlds Fair award winning Terracotta Building which was formerly the office and showroom of the Celadon Terracotta Tile Company that operated in Alfred from 1892-1908 when the whole factory then burned down, save for the Terracotta Building, perhaps because it was entirely clad in terra cotta and thus fairly impervious to exterior fire, I'm not sure, I didn't ask because I didn't have that thought until just now. Anyway, I cleaned up the building, made a body of work using a collection of historic terracotta tiles as bisque molds, and operated “The Mobile Anagama Company” out of it which was set up as a used mobile wood-kiln dealership of sorts, and I facilitated a free public woodfiring workshop on the lawn next to the building as part of it. Some portion of my interest in putting together the project as I did was about looking at the relationship between The Mobile Anagama and The Terracotta Building, about what a structure communicates through its form, material, color, context, signage, etc; how the two structures operated as functional sculptures and how their character influences your perception of the space and activities around them. But something I wasn't thinking about was how well terracotta tiles could function as the roof of a building-like-kiln, but when I did have that thought it was immediately clear that this was the answer. So I found a person selling a bunch of reasonably priced and lovely looking terra cotta roof tiles in a nearby suburb, but when they turned out to have been made by the Ludawitchi Celadon Terracotta Tile Company, it felt like some wild coalescing magic affirmation.

Looking back on building this kiln now it is all kind of this fuzzy beautiful blur because we were just working so hard to get the kiln finished before the winter and fired before the holidays, but the truth is that kiln building is slow, tedious and tiring work, and I really cannot give enough credit to all our dear friends who showed up with so much generosity and enthusiasm to make what could have been a long cold difficult fall into a continuous string of joyous occasions no matter the weather. Al, Taylor, Sunny, Esme, Caroline, Beck, Brian, Drew, Phil, Ayaka, Loren, Ryan, Mo, T, Jacinta, Chris, Colin, Adrian, Heath, Leo, Braden, Olivia, Juan, Dan, Jules, Travis, Julie, Steve, Chris R, Dani, Nathan, Stephen, Sejal, Irena, Klair, Elise, Carrie, Diana, Ben T, Erin, Gabriel, Marcella, Maya, Matt, Cody and Elliot all deserve awards and piles of money! And my sincere apologies to all those I surely forgot to list - my brain is still a bit fire fried!

I am a deeply lucky person in so many ways, and I feel especially so to have gotten to build and fire my first kilns while I was a student, and to have been able to continue to make designing, building, firing and teaching around wood-fired kilns such a central part of my life. I have long held romantic notions about ceramics as a catalyst for a kind of critical and empowered community that can work in opposition to so many of the sad and unfortunate aspects of today’s world, and its experiences like what we’ve just had with our new kiln here that continue to affirm my woo-woo gut assessment that ceramics, despite its carbon footprint and entanglement in the global extraction economy, can be a net positive force toward a more equitable, just, sustainable, peaceful and joyous world.

When I was a fellow at Oxbow School of Art and Artist Residencies in 2010, Theaster Gates was a visiting artist that summer, and he gave an incredible lecture as he does, and I remember him talking about his Dorchester Projects, about what he was making and making happen with this old house, and with his community, and he shared this question that really stuck with me about whether he wanted “to make a thing, or to make a thing that makes a thing, or to make a thing, that makes a thing, that makes a thing.” I remember thinking that question felt right on, that I thought that third level of thingness was the ephemeral happening, not the thing or the place, but the thing that happened with the people because of the thing and the place, and I felt like that illuminated so much about the artists I admired in Detroit whose creative work was extending beyond the studio and into the fabric of the city, and I also remember being completely unsure about what that could possibly mean for me and my work.

That fall of my junior year at the College for Creative Studio, the then Crafts Department moved locations on campus, and we built all new kilns including a Manobigama wood fired kiln. Our professor Tom Phardell managed to lead us in building a gas reduction kiln, a baby salt kiln, a large salt kiln and the wood kiln all during that semester, and reflecting back on this with the experience I have now, he was clearly doing a super-human amount of background work that I’m sure he didn't receive nearly enough recognition or compensation for, and I will forever be grateful for his making the process of building a kiln seem way easier than it really was. And as a lifetime pyromaniac it was love at first fire light and I remember realizing during the first firing that I wished I had a wood kiln that wasn’t on campus because as a 20-year-old I wanted to be able to stay up all night partying around it. But my second and more profound realization came shortly after that as it occurred to me that a kiln could be ‘the thing that makes a thing’, or even ‘a thing that makes a thing that makes a thing’.

A kiln can be so much more than a tool, it can be a beacon, a stage, a sculpture, a shrine, and a radical prompt to come together, to commune around a prolonged fire and a common goal, and to realize how it is that we might be able to change things. This new kiln, like so much of my life over the last 15 years, emerges in many ways from that epiphany.

Additional extra special thanks to Colin, Juan, Al, and Heath for making the chimney happen. I’d tell you how we did it, but I’d have to kill you! :o

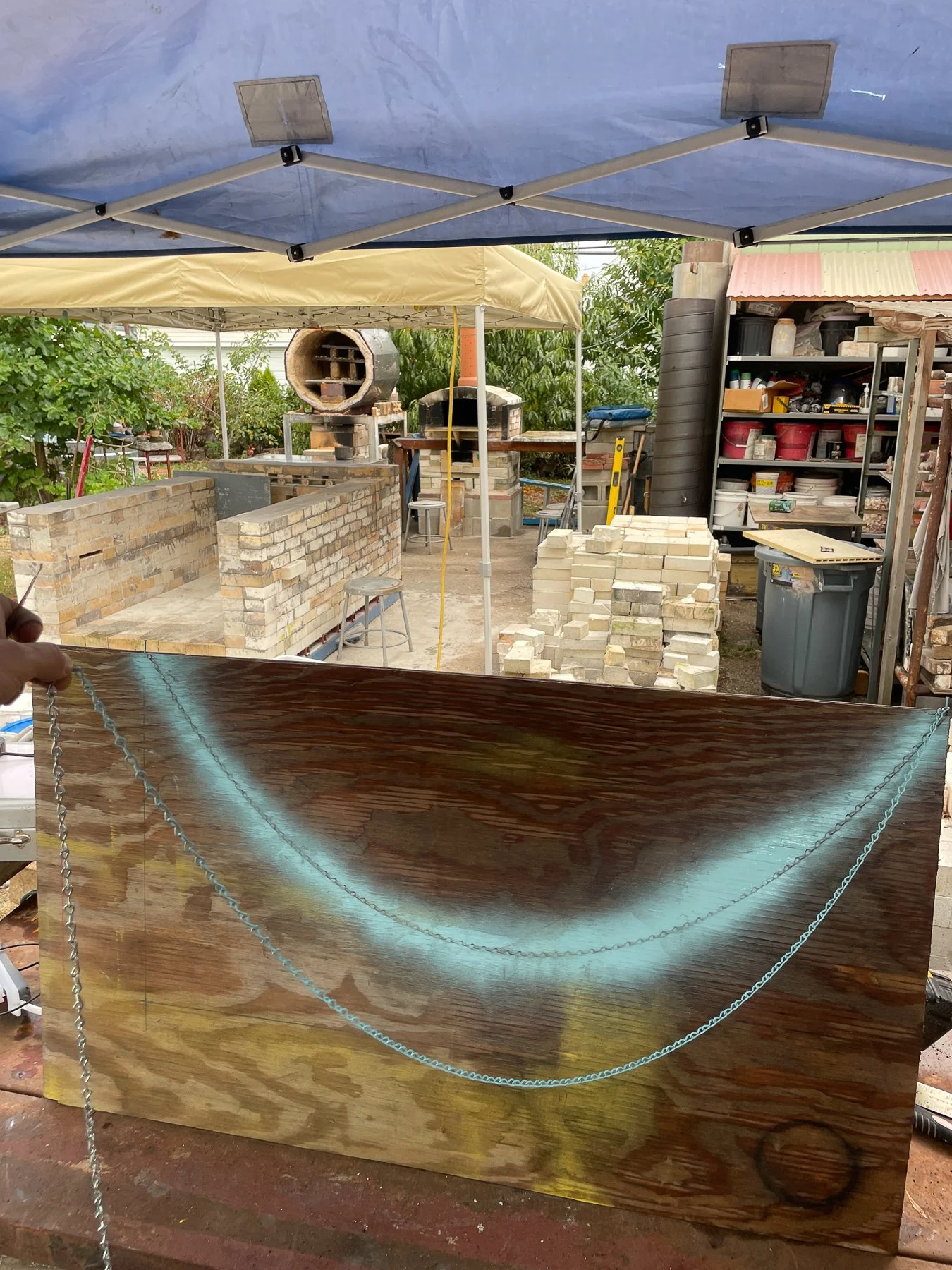

We’re calling it a ‘double decker kiln’ or a ‘three way kiln’, and also ‘The Hamtramckiln’ because the demonym for a person from Hamtramck is a Hamtramckin, and because its small rectangular footprint and tall two-story orientation feels very much inspired by the peculiar tall skinny rowhouses that populate most of Hamtramck. Whatever it is, it’s here, and it stares at us through our kitchen window every morning, and I can’t stop thinking about it, and about making things to fire in it, and firing it again!

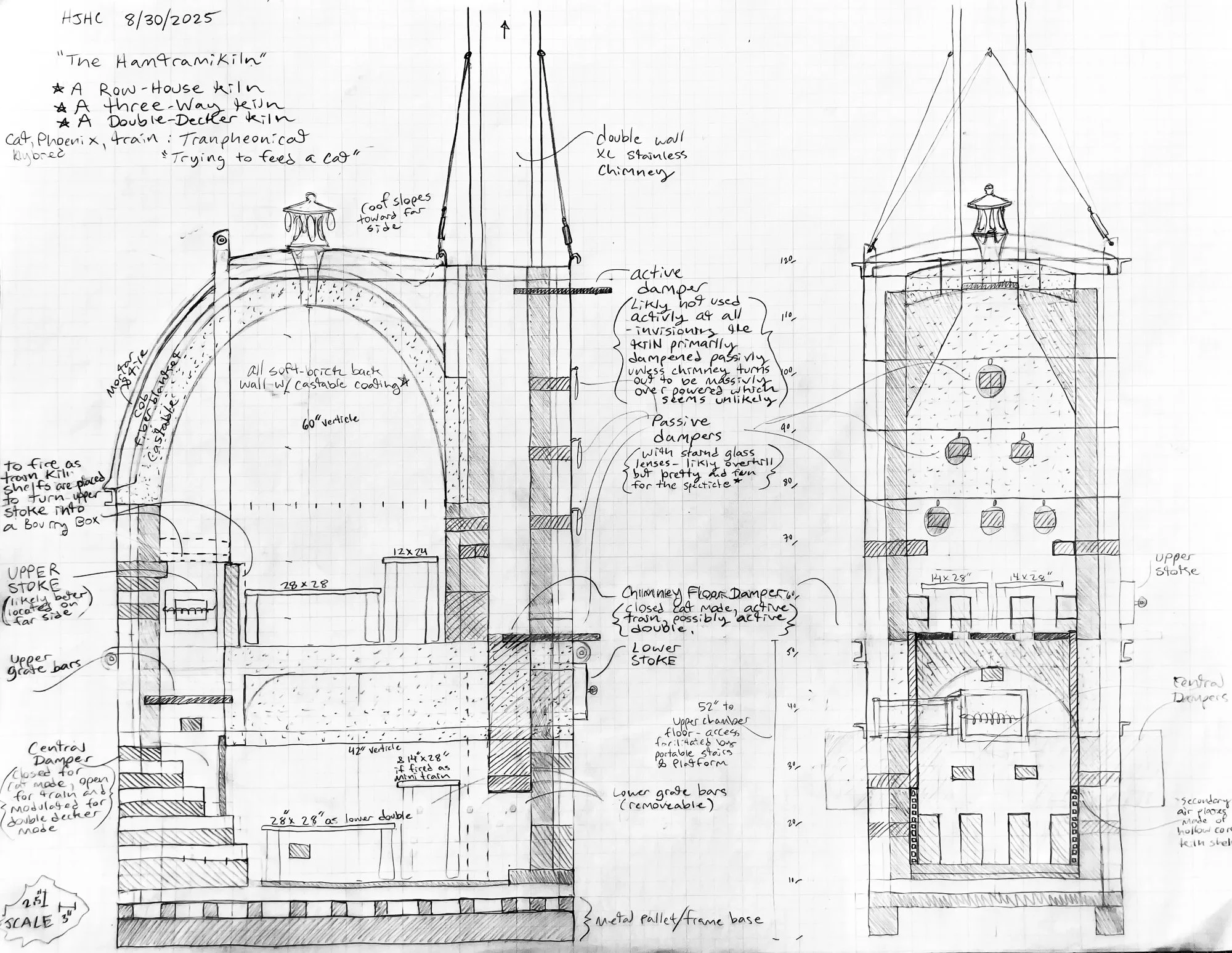

The Hamtramckiln, our Double Decker Kiln, is a two chamber kiln that can be fired in three different orientations. Both cambers can be fired at the same time, oriented like a phoenix kiln, like a climbing kiln turned back on itself wherein the upper chamber is above the lower chamber and the chimney is above the main firebox (which was the orientation of our maiden firing). Or either the upper chamber or lower chamber can be fired independently, the upper as a catenary arch kiln, or the bottom can fire backwards as a train kiln by temporarily stacking bricks and placing kiln shelves to close off the top of the upper firebox, and opening the ‘chimney floor dampers’ that baffle two large openings that directly connect the chimney to the lower chamber above the lower firebox. If that doesn’t make sense, my apologies - hopefully the drawings can help to clarify that a bit.

The Double Decker kiln design is also very much in response to Hamtramck being the most densely populated city in Michigan, and so it needed to be in line with city ordinances, and able fire without smoking out our neighbors. Orienting the kiln like a phoenix kiln with one chamber on top of the other, both enabled a foot print small enough to work on a pallet, and offers easy observation of the chimney and control of the chimney base dampers and passive dampers which are all located just above the lower firebox which is where the primary activity of firing takes place when firing both chambers of the kiln. This orientation, which places the firers simultaneously in front of the firebox and the chimney, allows for very careful control of smoke which any kiln could be made to produce in excess, but which this kiln is intended to be able to fire without quite easily. Opening the chimney base dampers slightly during the firing also seemed to be effective in super heating the chimney and in aiding to combust any smoke that would have come out of it. Perforated kiln shelves were also built into the walls of the kiln to offer optional preheated secondary air and preheated passive dampers in the chimney, both of which hypothetically aided in our smokeless effort. All of these things seemed to work well, but it’s far too soon to say with any certainty what really does what yet with this new kiln!

What I can say is though that the brickwork, refractory castings, metal fabrication, ceramic tile roof and chimney all look great and seem to have fared the first firing and first bit of winter swimmingly. The kiln was intended to fire efficiently, and even with the prolonged first firing where we dried out the kiln below 212 degrees for 26 hours before proceeding to limit our climb to 100 degrees an hour on our way up to our target temperature as per the castable’s instructions, we used just under one cord of cut offs from the lumber mill a couple miles up the road, and we burned the better part of a face-cord of fire wood in our effort to stay warm in front of the kiln. The first firing was very much a test of both the kiln and us firers, as the weather went from snow to slush, to rain, to single digits and wind while we loaded and then fired, and although the kiln isn't totally totally done yet as it was too cold to apply the protective refractory mortar we intend to spread over the exterior bricks, and the paint job on the metal isn't totally done either, it is functionally finished, and it's definitely been fired thanks to our amazing friends.

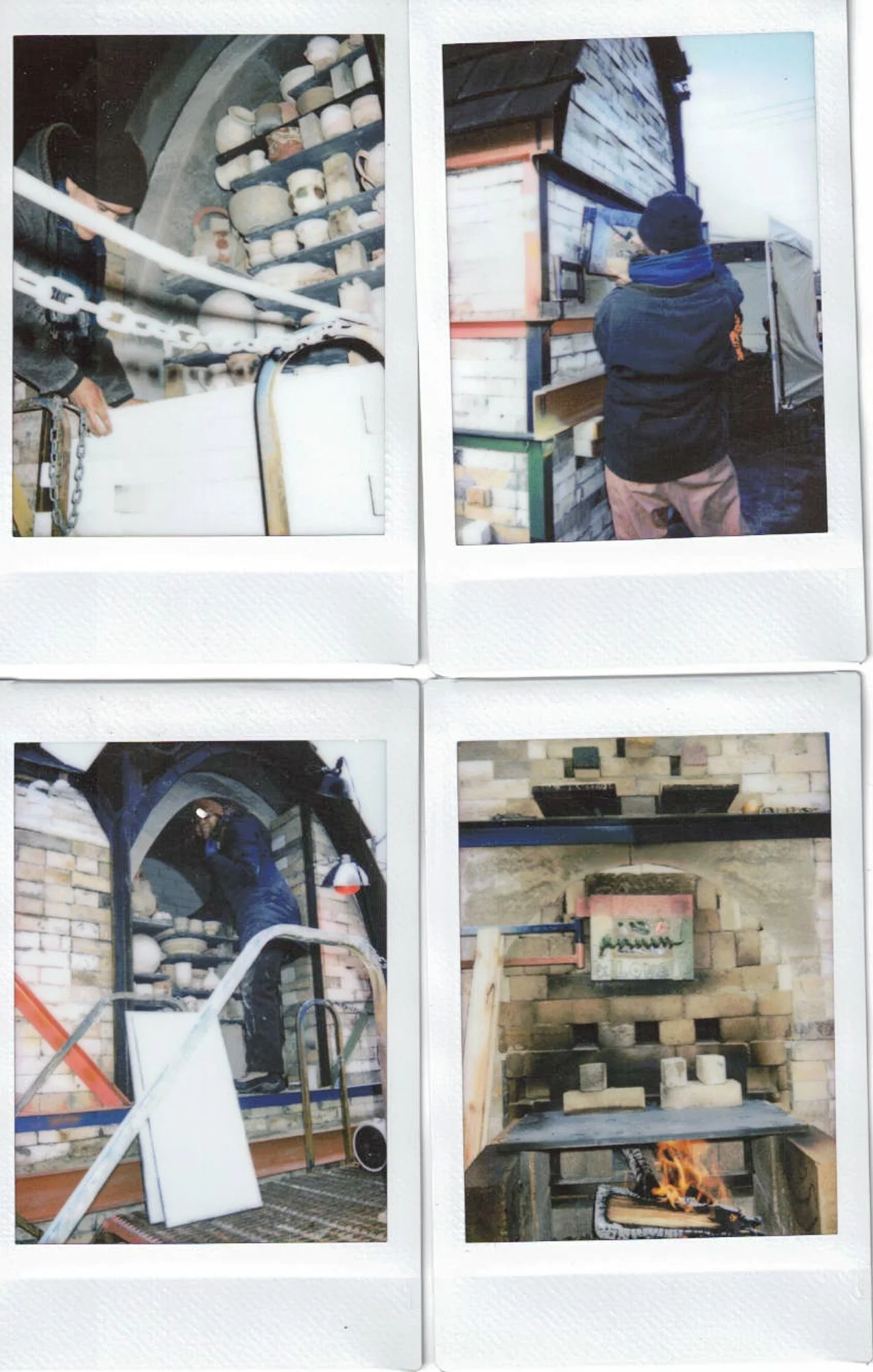

Dan and Jules came from Sanoma, CA and stayed for the better part of three weeks as our special wood-firing resident artists, and it would be impossible to overstate how awesomely helpful and essential they were to pulling this first firing off, despite Jules having never previously seen snow! They both led the charge on the seemingly endless list of tasks that needed completion before the first firing could begin; moving and sorting biles of bricks, cleaning out the kiln, making and applying the ‘working potters ITC coating’ that they painted onto all of the exposed k26-60 brick surfaces on the interior of the upper chamber, mixing up the wadding, mixing the kiln wash and painting multiple coats on the new kiln shelves, and cutting and moving a majority of the wood we fired with.

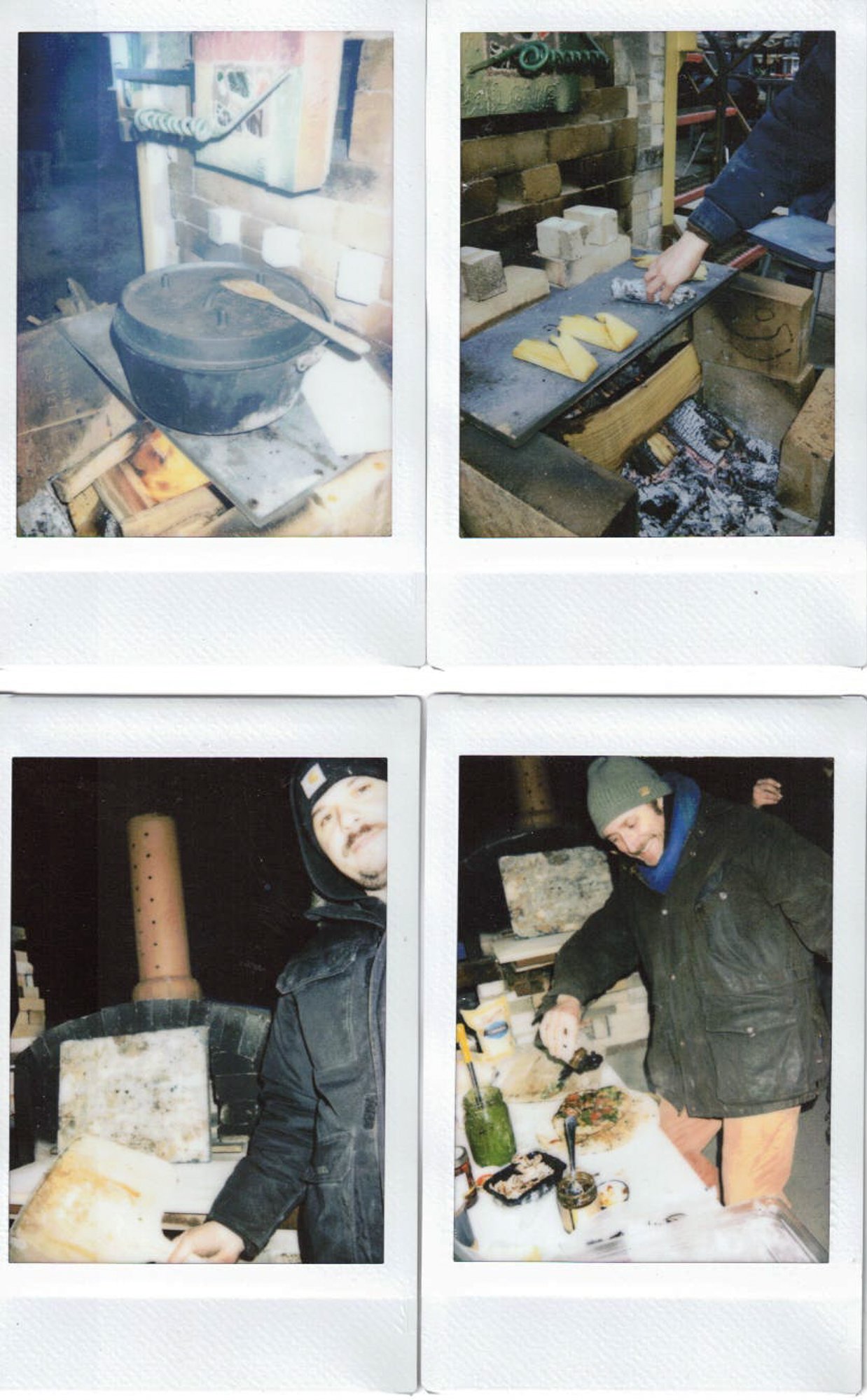

We get wood strippings in 30’ diameter 16’ long bundles forklifted onto our trailer at the lumber mill, and after cutting, moving and stacking the thousands of cut pieces that all too often fall in a jumble is an hours long game of pickup sticks. We have an absurd game we play where we name every piece of wood. Names quickly morph to include subjects, concepts, anything really. “This is Girizelda, this is a dream Grizelda had, this is a movie titled Grizelda’s Dreams featuring Gweneth Paltrow as Grizelda’s therapist.” It seems to work best while moving larger pieces of wood by human chain, but no matter the method something about moving wood with friends always seems to bring out the sillies in a way that plays some critical role in helping to set a tone of comfort and play around this big fairly intense wood firing situation that could quite easily instead be intimidating or overwhelming.

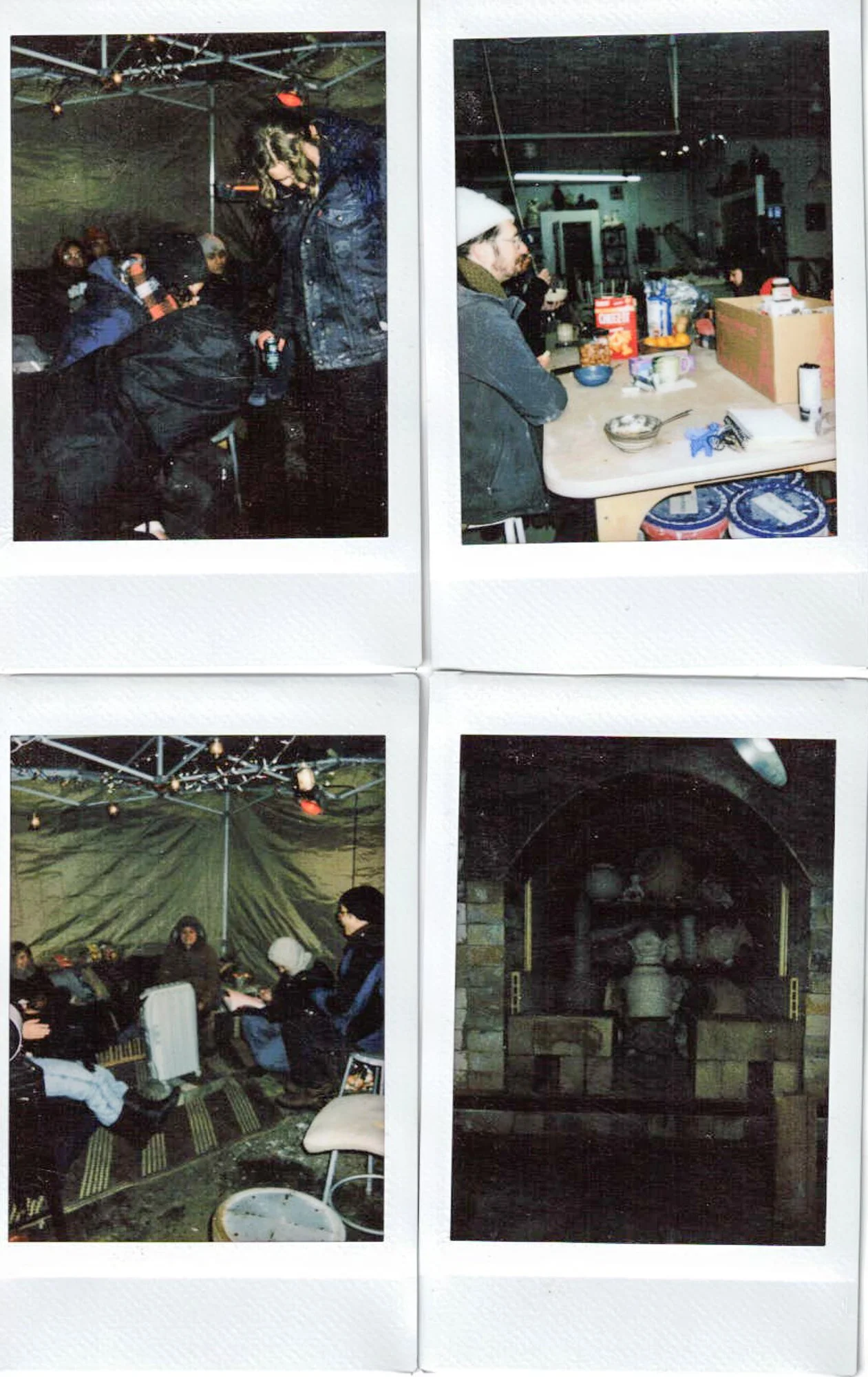

To enable the day's long project of loading the kiln, and to keep us shielded from the elements while we fired, we set up and strapped down a 10’x10’ canopy tent with 3 sides, and filled it with shelves that we covered with objects to be loaded into the kiln. Once loaded we borrowed a couch from our neighbor Emily’s greenhouse and did our best to convert the tent into a cozy fireside living room.

Loading a wood kiln in the freezing cold is a good trick, as the refractory clay wadding that we use to keep ceramics, and kiln shelves and stilts from getting glazed together by the ash and atmosphere in the kiln can freeze, especially when it comes in contact with the kiln shelves that are particularly good at conducting heat, or in this case, cold. Putting a space heater in the kiln and keeping the wadding under a heat lamp both helped a lot, but keeping our fingers warm enough required taking frequent turns in the studio to warm up. We finished loading the kiln and bricking up its doors on that Thursday after midnight as we expected we might, and reconvened the following morning for the inaugural lighting ceremony.

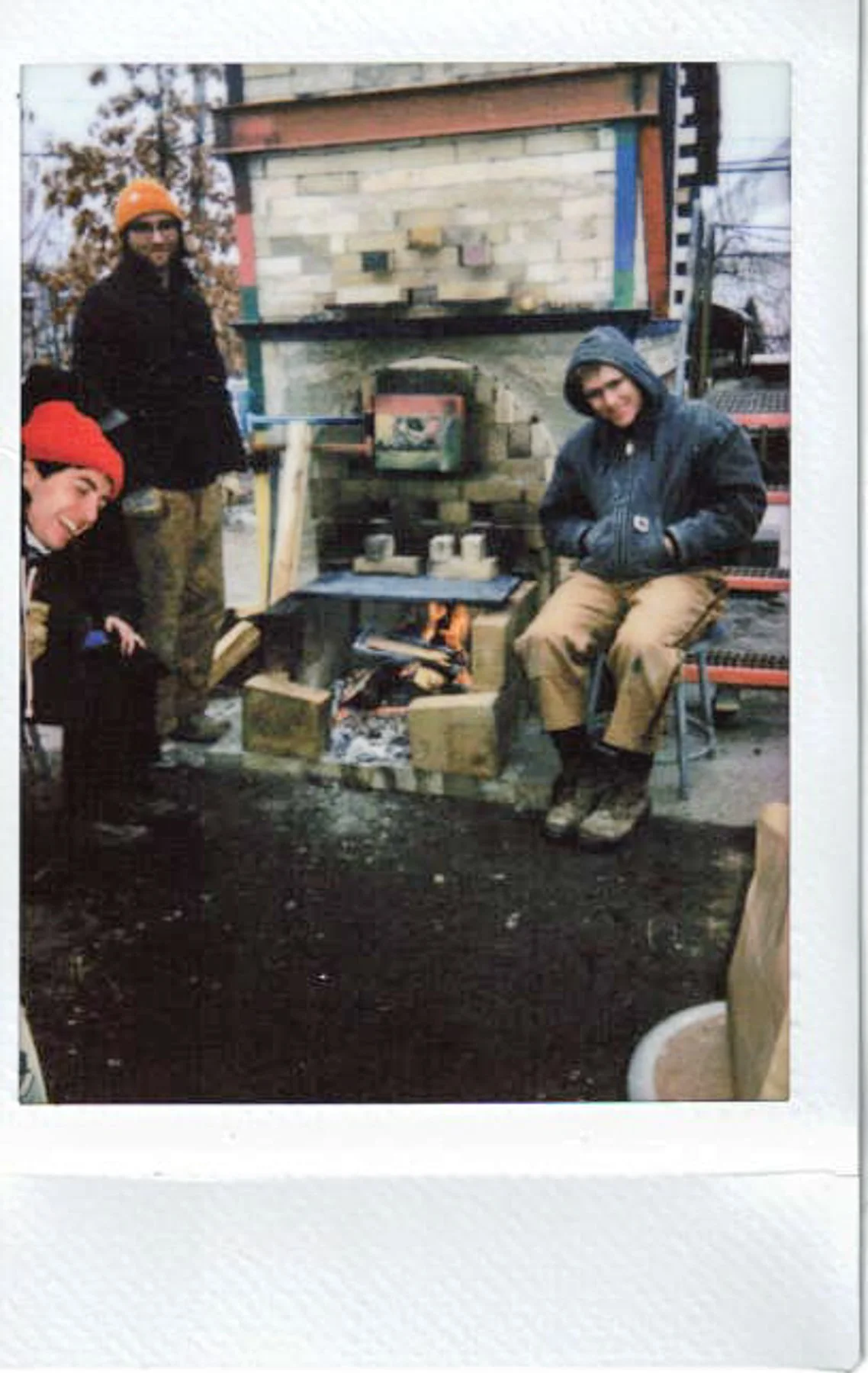

That morning we constructed the ‘pig nose’ where the fire would begin in front of the kiln because maintaining a fire inside the kiln without the kiln quickly jumping above boiling point would be a near impossibility, and because it was essential to have a fire burning in front of the kiln for the entire duration of the firing to keep us from freezing our butts off! At 11am we gathered around the kiln with coffees, and I did my best to hold back tears while trying to speak to the context of this activity we were all engaging in, of where we were currently, of the seemingly neverending train crash of our world sick with late capitalism, touching on many of the same little antidotes above, and something about the poetry of how these materials and stories have seemed to converge, and the incredibly unlikely and unpredictable beauty that I am so grateful to know and love. Virginia tried to pour the kiln a drink as an offering and instead fumbled and broke a cup on the kiln, accidentally and also appropriately christening the ship on its maiden voyage. Drew brought a curated ‘bag of poems’ that people pulled and read from, and Stephan sang a Lacota song was one of the more beautiful things I’ve ever witnessed. All those present who had never fired a wood-fired kiln before lit the fire together, and so began our 3 day journey.

People had signed up for 6 hour long firing shifts, 2pm-8pm, 8pm-2am, 2am-8am, 8am-2pm, and so on, and in truth the firing was a breeze for the most part, albeit a cold one. On that Friday night while the kiln sat around 200 degrees drying out, we sang Kiln-a-oke, another tradition started at Oxbow wherein we sing songs about fire and transformation to appease the kiln gods. The pizza oven was warm nearly the whole time with Klair facilitating pizzas on Friday, Travis on Saturday, and I’m pretty sure Caroline and Diana both independently made Ficashas on Sunday. Our tummies were full, spirits were high, and the energy was infectious.

As an auspicious illustration of this, on the late late Friday night shift that’s actually the early early Saturday morning shift, as the kiln was still only in the drying out phase, it was 7am, 7 degrees outside and there were 7? of us around the kiln enjoying the incredible contrast of our hot shins and cold butts as the sun began to rise. This was way more people than were needed, but the excitement was that high even on the coldest night we’ve had in probably years.

Everyone had three layers of pants on and multiple socks as well. If they hadn't fired a wood kiln before you wouldn't have known it by watching the crew on Sunday and everything was going exactly as planned, until mid Sunday when the bottom chamber was nearing temperature and we decided to push in the ‘central dampers’ that slide in and out to open or constrict the throat between the lower and upper chamber, a feature inspired by the dampers that function similarly to close off the front ‘egg’ chamber of Josh Copus’s Community Temple kiln that we fired with him and several other lovely folks this last Spring of 2025 while Virginia and I were resident artists at Township 10.

The thermal shock of moving the very cold dampers in too quickly broke both of them dramatically and simultaneously, and all the sudden we were in a bit of a crisis management situation. The dampers held in place in their then much more constricted position, but they were no longer able to be reopened, and this all but forced the end of the firing in the lower chamber a bit sooner than we had intended. We then began reduction-cooling the lower chamber, keeping the chamber in a state of reduction by maintaining indicator flames licking out of a few small choice openings, and accomplishing this by feeding small sticks through a peep in each of the two fire boxes as the kiln cools down to a cherry red heat. While we down-fired the bottom we continued to fire the upper chamber solo. Feeding sticks into the upper firebox, it took off like a rocket, quickly reaching and proceeding to climb past our target temperature while we worked quickly to finish sealing up all the little openings in the doors and around the peeps with silica fiber blanket and refractory slip. Once sealed up we called the upper chamber up-firing finished, closed the chimney with the active damper, and began an effort to reduction-cool the upper chamber of the kiln as well. The reduction-cooling required surprisingly frequent stoking for several hours and the kiln was cooling slower than we had time or energy for, so we decided to call the down-firing finished prematurely. On our final once before putting the kiln to bed we found that the kiln’s active damper had been hung up on a little crack and was not actually entirely pushed in, and that this was the cause for the surprising rate at which it was consuming our down-fire sticks. I suspect down-firing will look very different next firing.

Despite those few unexpected challenges, the first firing was truly a magical event that I will not soon forget, and I think the results of the firing were fantastic considering it was the first firing with this new kind of kiln. We reached cones 11 and 10 on most of the bottom and cones 12 and above on most of the top, but the bottom was more uneven and less melted than we would have liked, and the top was a little hotter and more oxidized than I had hoped. Leading up to the firing I kept telling people that I couldn't wait to be deep in the firing and thoroughly confused by the kiln. I certainly got what I wished for and am thrilled to have learned these unexpected lessons. With them in mind I am chomping at the bit to fire it again soon and to experience what it will teach us next thanks to the information we have now.

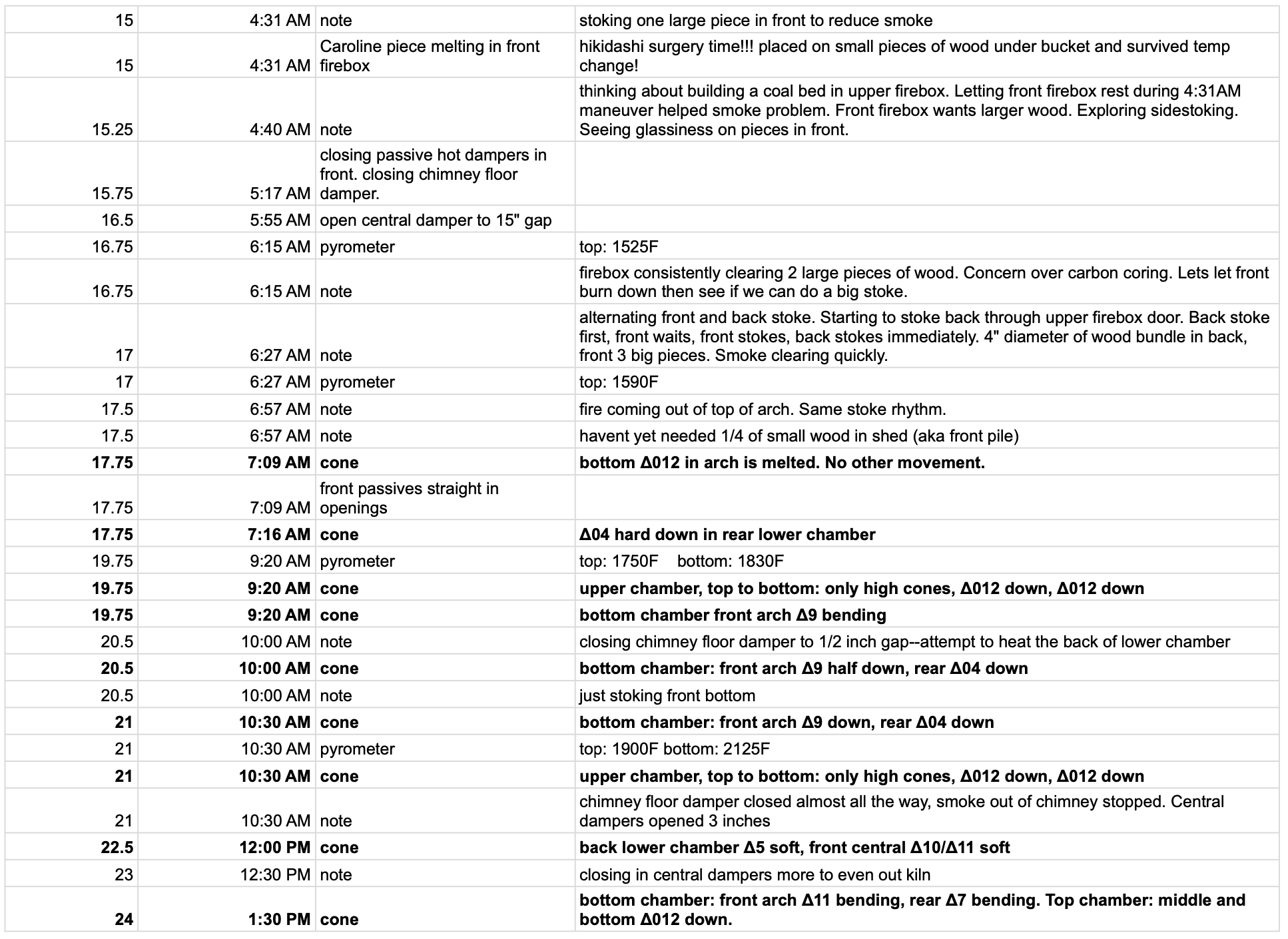

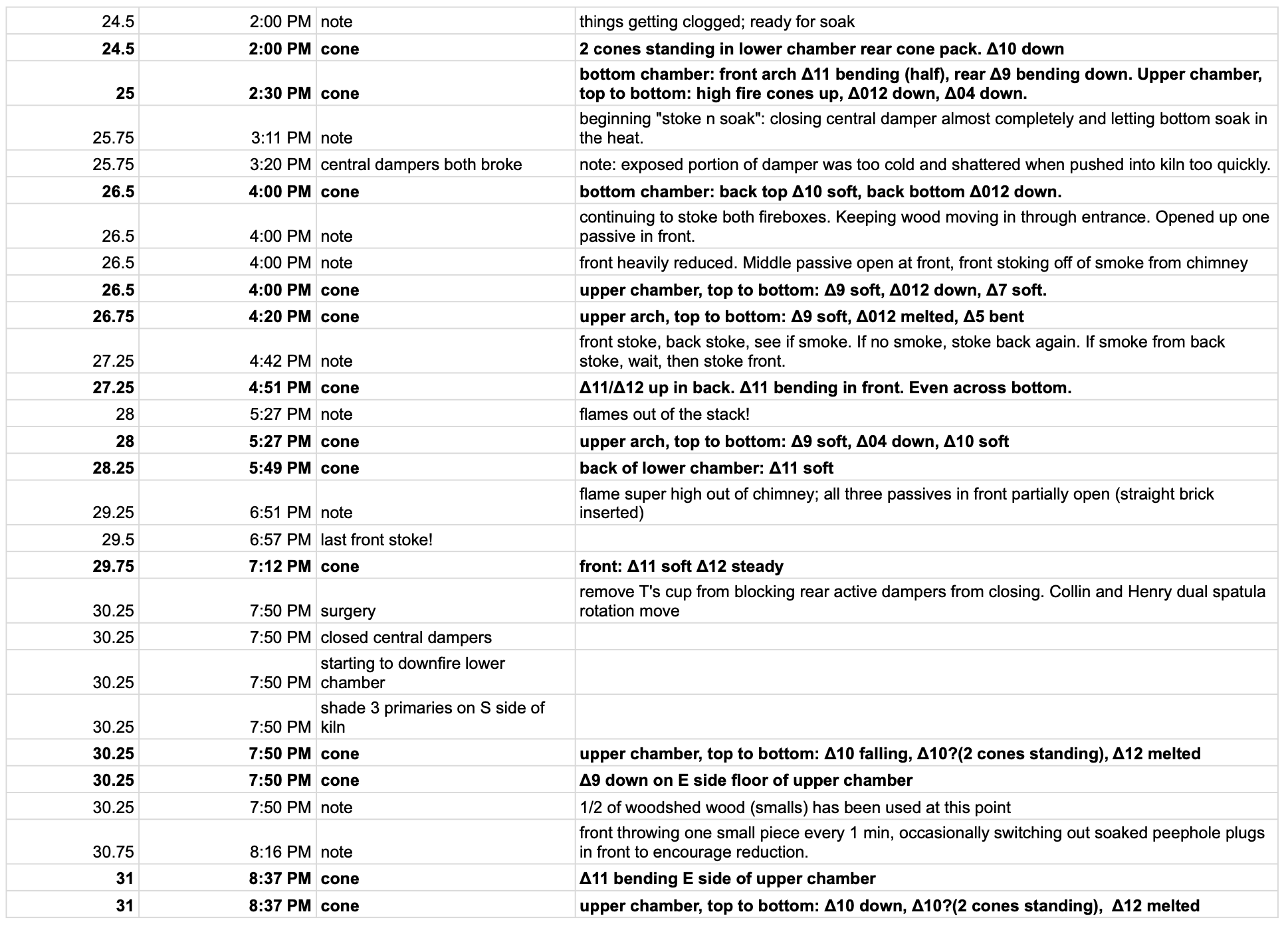

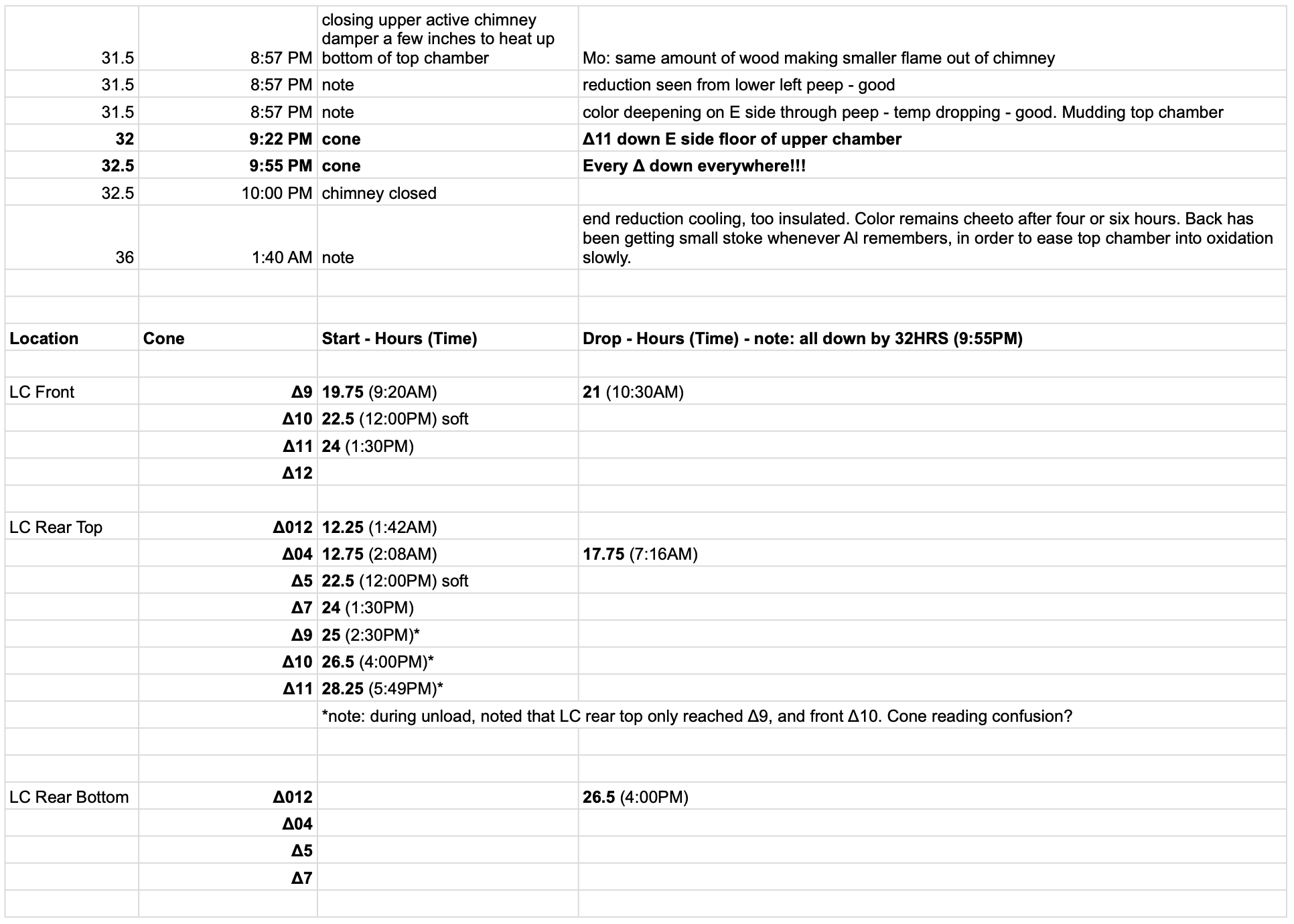

If seeing a big sheet of numbers and observations recorded in time is of interest, please enjoy this kiln log that Taylor kept and digitized. The temperature readings were taken with an ancient analog pyrometer that proved to be incredibly inaccurate and she noted that there were some inaccurate readings about what cones were bending where, but perhaps it offers a general idea. Taylor would hate for me to single her out in this way, but she made the drive up from Cleveland every weekend to build the kiln and then stayed for the entire duration of the loading and firing, and kept the kiln log despite a tooth ache that resulted in a nbd mid firing extraction, and like holy shit and we really just couldn't have done it without her, and it wouldn't be fair to not give her a giant shout out for being such a total bad ass.

So many things excite me about this kiln, what it will bring to our community, how it is a response to our location here in Hamtramck, how it emerges from and combines so many of the kilns I’ve known and fired, and that its three optional orientations might offer as large a range of possible surface outcomes so as to feel relevant to as many of our members and resident artists who we might fire it with us someday. And I'm especially interested to see where it takes mine and Virginia’s personal ceramic work as we both hope to find more time and energy to put toward our personal making practices in the years to come.

Currently we’re half hoping for an unseasonably warm February so we might find a weather window in which to fire the kiln again before we fire it yet again in March as part of *NCECA* which will be in Detroit this spring for its 60th annual conference. We worked so hard to make all of this come together last fall that I think Virginia and I both ended 2025 feeling a bit totally burned out exhausted, but we’ve had a needed slow start to the new year and I think we are both beginning to feel the wind in our sails again as we are heading full speed into a what promises to be a very exciting spring here.

And what all of this is to say really is just to express my incredible gratitude for everyone that came together to make all of this possible, and what a privilege it is to get to work to share our studio with our community every day. To have this kiln as part of it now is truly a dream and I look forward to sharing more about it as the story unfolds.

And if somehow you’re still reading this, I’ll just end with one more thank you for your time and interest. I expect future blog posts will be a fair bit shorter, but I felt like I needed to really dig into the back stories to get grounded with this initial one. If you're reading this prior to March 25th, 2026, and will be in Detroit for the big NCECA conference this spring, please do stop by Ceramics School because we’ll be firing the kiln, hosting a “Trophy Life” exhibition and launching a big surprise! If you'd like to be kept up to date with details about things going on at our studio, upcoming firings, classes, visiting artist presentations, exhibitions, etc, please sign up for our mailing list on our website. www.ceramicsschool.com

All my warmest ICE melting fireside wishes of love and wellness,

-Henry JHC

A few of my and Virginia’s pots from the first firing of The Hamtramckiln